Structure design and simulation research for the water-cooled solenoid with 1.5 T magnetic field

-

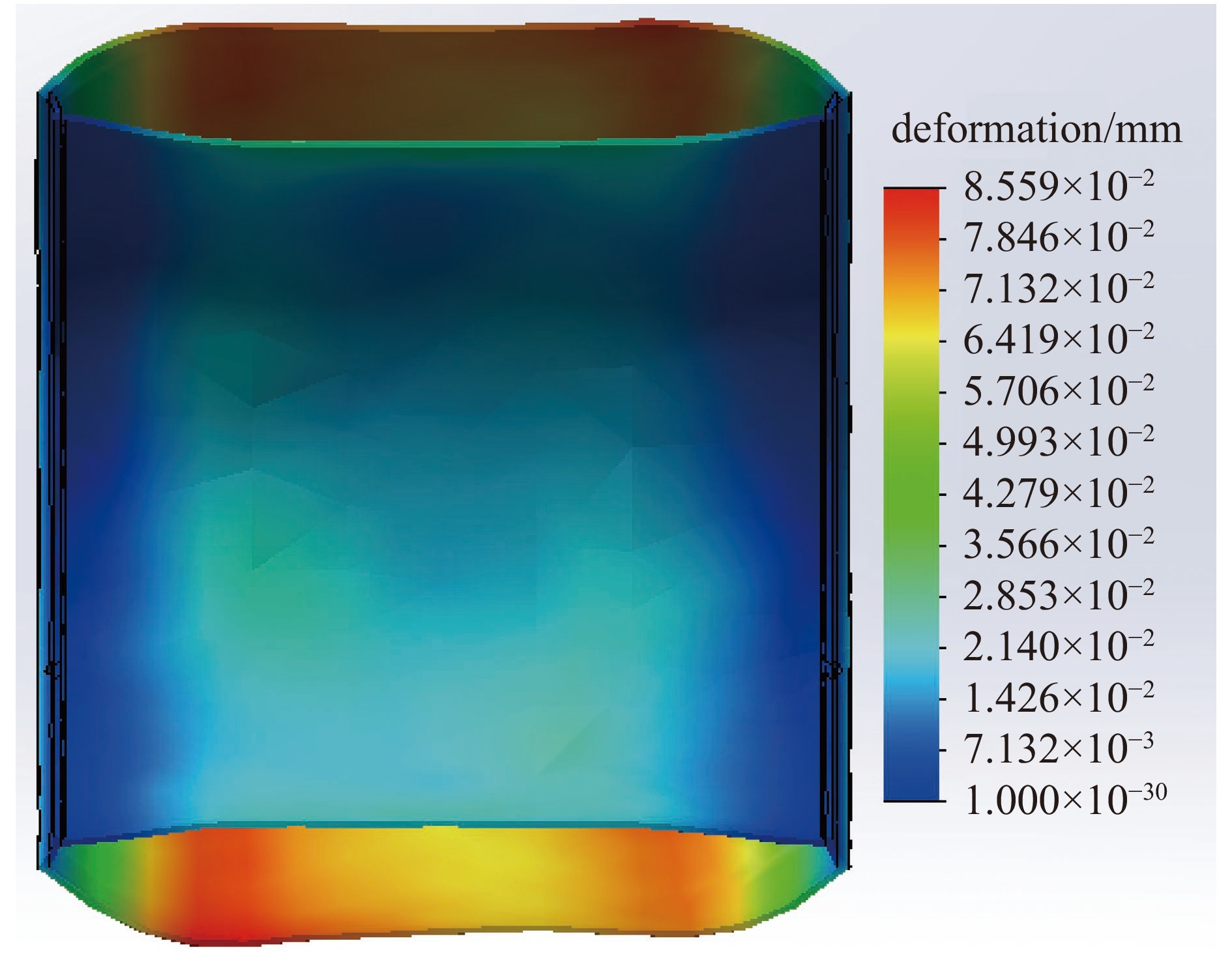

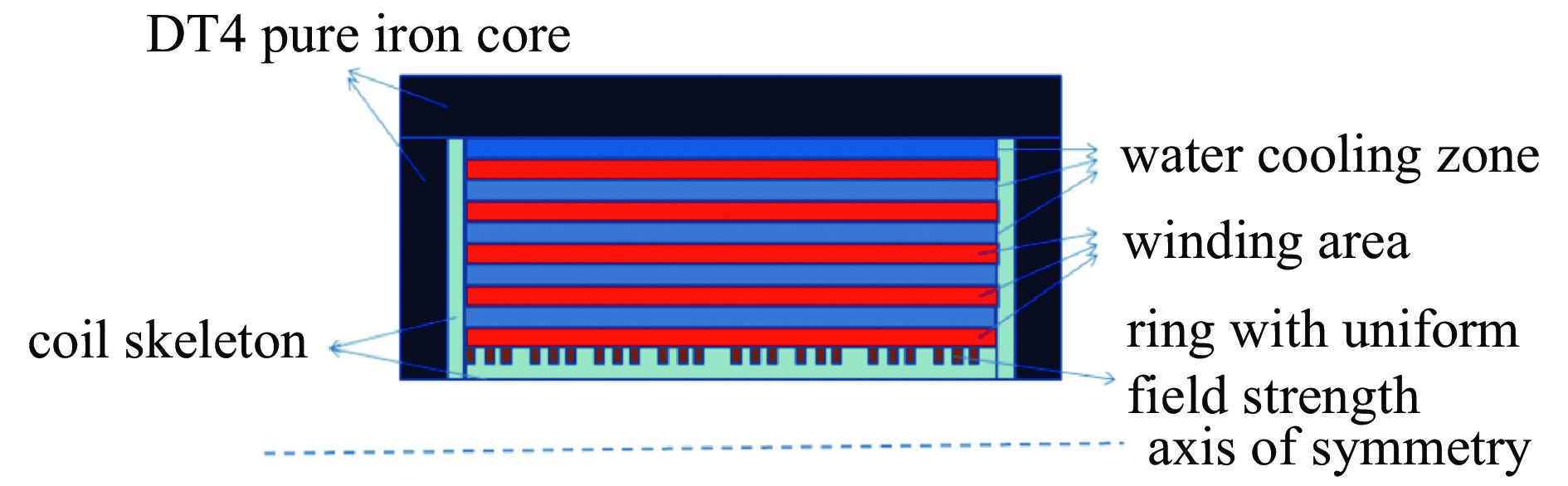

摘要: 介绍T量级水冷式螺线管线圈的结构设计及仿真研究工作。采用多层水冷结构设计,对不同温升导致的变形量进行计算并校核,最后利用POISSON程序对线圈磁场进行仿真计算。计算表明:最大温升60 ℃时,整个结构变形量小于0.07 mm,即探头相对位置变化量可小于0.1 mm;96.6 A电流加载时,中心区最大磁感应强度为1.5 T;0.01%精度轴向磁场宽度为40 mm,0.1%精度轴向磁场宽度为140 mm。从仿真结果来看,设计的水冷式螺线管线圈可满足磁场探头校准测量要求。Abstract: The structure design and simulation research for the water-cooled solenoid with magnetic field on the order of T are presented in this paper. The multi-layer water-cooled structure design is used for the solenoid. The solenoid structure malformation caused by different temperature rise is simulated and checked. Finally the magnetic field is calculated by POISSON code. The structure deformation is less than 0.07 mm with 60 ℃ temperature rise and the magnetic field is 1.5 T with 96.6 A current.The axial magnetic field region is 40 mm on the order of 0.01% precision and is 140 mm on the order of 0.1% precision. The results show that the water-cooled solenoid is good enough for the magnetic field calibration measurement.

-

Key words:

- water-cooled /

- solenoid /

- calibration

-

表 1 冷却水温升60 ℃以内的线圈结构变形仿真结果

Table 1. Simulation results of coil structure deformation with cooling water temperature rise within 60 ℃

cooling

water

temperature

rise/℃maximum deformation of

stainless steel water

cooling cylinder

at the maximum outer

diameter/10−2 mmmaximum

deformation

of the overall

structure of the

coil/10−2 mm10 4.688 3.194 20 4.282 3.042 30 4.879 4.561 40 5.945 5.343 50 7.240 6.135 60 8.559 6.973 表 2 90A线圈加载电流计算结果

Table 2. Calculation results of 90A coil loading current

winding area number turns length/m resistance/Ω power/kW voltage/V 1 1000 300 0.46 3.73 41.4 2 1000 676 1.04 8.42 93.6 3 1000 1122 1.72 13.93 154.8 4 1000 1563 2.40 19.44 216 5 1000 2004 3.07 24.87 276.3 -

[1] 陈继忠, 张一鸣, 肖继军. 低场核磁共振螺线管线圈的设计[J]. 分析仪器, 2007(2):21-25 doi: 10.3969/j.issn.1001-232X.2007.02.006Chen Jizhong, Zhang Yiming, Xiao Jijun. Design of solenoid coil for low field NMR[J]. Analytical Instrumentation, 2007(2): 21-25 doi: 10.3969/j.issn.1001-232X.2007.02.006 [2] 荆晓兵, 陈楠, 李勤. 宽平顶低横向场分量螺线管线圈设计[J]. 强激光与粒子束, 2010, 22(3):591-594 doi: 10.3788/HPLPB20102203.0591Jing Xiaobing, Chen Nan, Li Qin. Design of wide flat-topped low transverse field solenoid magnet[J]. High Power Laser and Particle Beams, 2010, 22(3): 591-594 doi: 10.3788/HPLPB20102203.0591 [3] 梁羽, 马力祯, 吴巍, 等. 2.0T斜螺线管型超导二极磁体设计[J]. 低温与超导, 2017, 45(8):51-56 doi: 10.16711/j.1001-7100.2017.08.010Liang Yu, Ma Lizhen, Wu Wei, et al. Design of a 2.0T superconducting dipole magnet based on tilted solenoids[J]. Cryogenics & Superconductivity, 2017, 45(8): 51-56 doi: 10.16711/j.1001-7100.2017.08.010 [4] 臧宗旸, 龙全红, 荆晓兵, 等. 基于激光跟踪仪测量方法的磁测探头空间位置测量[J]. 机械工程师, 2019(4):124-125 doi: 10.3969/j.issn.1002-2333.2019.04.042Zang Zongyang, Long Quanhong, Jing Xiaobing, et al. Space position measurement of magnetic probe based on laser tracker measurement method[J]. Mechanical Engineer, 2019(4): 124-125 doi: 10.3969/j.issn.1002-2333.2019.04.042 [5] 熊娟, 魏薇, 王芳, 等. 螺线管磁场设计的简易仿真分析方法[J]. 大学物理实验, 2021, 34(2):33-36 doi: 10.14139/j.cnki.cn22-1228.2021.02.009Xiong Juan, Wei Wei, Wang Fang, et al. Simple simulation analysis method for solenoid magnetic field design[J]. Physical Experiment of College, 2021, 34(2): 33-36 doi: 10.14139/j.cnki.cn22-1228.2021.02.009 [6] 牟凡, 董攀, 代志勇. 铁氧体加速腔螺线管线圈温度测量[J]. 强激光与粒子束, 2010, 22(4):825-828 doi: 10.3788/HPLPB20102204.0825Mu Fan, Dong Pan, Dai Zhiyong. Temperature measurement of accelerator cell solenoid loop[J]. High Power Laser and Particle Beams, 2010, 22(4): 825-828 doi: 10.3788/HPLPB20102204.0825 [7] 牟凡, 董攀, 代志勇. 直线感应加速腔螺线管线圈温升效应研究[J]. 高能量密度物理, 2010(1):9-11,34Mu Fan, Dong Pan, Dai Zhiyong. Research for temperature effect of accelerator cell solenoid[J]. High Energy Density Physics, 2010(1): 9-11,34 [8] 张华辉. CFETR中心螺线管模型线圈应变和位移实验设计与分析[D]. 合肥: 中国科学技术大学, 2017Zhang Huahui. Experimental design and analysis of strain and displacement of CFETR CSMC[D]. Hefei: University of Science and Technology of China, 2017 [9] 彭楠, 熊联友, 刘立强, 等. 3T超导螺线管标准磁铁的研制[C]//第八届全国低温工程大会暨中国航天低温专业信息网2007年度学术交流会论文集. 2017Peng Nan, Xiong Lianyou, Liu Liqiang, et al. The research of standard ferromagnet for 3T superconductive solenoid[C]. 2017 -

下载:

下载: