Review of the research on electrode erosion of gas spark switch

-

摘要:

气体火花开关是脉冲功率装置中最常用的关键器件。电极烧蚀作为脉冲功率开关中的难点问题,会引起开关自击穿电压降低、触发抖动增大及开关寿命降低,已成为制约气体开关发展和应用的一个瓶颈。本文回顾梳理了国内外学者针对电极烧蚀问题进行的一系列研究,从电极烧蚀理论和实验研究成果两个方面,介绍了电极烧蚀的基本机制及仿真模型,归纳了影响开关电极烧蚀的因素以及电极耐烧蚀材料的研究进展,最后讨论了电极烧蚀研究面临的问题以及优化电极材料抗烧蚀性能的方向。

Abstract:Gas spark switch is the most commonly used key device in pulse power device. The difficult problem of electrode erosion, which affects the performance of gas spark switches, has always become a bottleneck restricting the development and application of gas switch. This article reviews the existing electrode erosion theory and experimental research results, introduces the basic mechanism and simulation model of electrode erosion, summarizes the factors affecting the switching electrode erosion and the research progress of erosion-resistant electrode materials, and finally discusses the problems faced by the erosion research and the direction of optimizing the erosion resistance of the electrode materials.

-

Key words:

- gas spark switch /

- electrode erosion /

- erosion mechanism /

- erosion model /

- electrode materials

-

表 1 电流峰值13 kA和电荷量17 mC时电极烧蚀特性

Table 1. Erosion characteristics of electrode at 13 kA peak current and 17 mC charge

n anode cathode pit depth/μm height of salient/μm erosion mass/ng pit depth/μm height of salient/μm erosion mass/ng 2 8.95 1.92 128.7 9.28 3.46 127.3 5 8.77 3.42 97.0 7.46 4.95 98.9 6 8.15 4.55 92.1 8.06 4.98 93.9 表 2 常见材料的物理参数及熔化“冲动性”参数[31-32]

Table 2. Physical and melting “impulsivity” parameters of common materials

material ρ/(g·cm−3) k/(W·cm−1·K−1) c/(J·g−1·K−1) Tm/K melting “impulsivity” parameter Cu-70%W 13.81 2.40 0.209 3061 8056 graphite 2.25 2.50 0.720 3970 7989 Cu-80%W 15.15 2.10 0.186 3216 7823 W 19.25 1.73 0.134 3680 7774 Cu-90%W 16.75 1.74 0.159 3302 7108 Cu-50%W 10.78 2.80 0.260 2521 7062 Mo 10.28 1.38 0.251 2896 5465 Cu 8.96 4.01 0.385 1358 5051 Ag 10.49 4.29 0.233 1235 3999 Cr 7.14 0.87 0.440 1875 3099 Au 19.30 3.18 0.129 1064 2994 Fe 7.87 0.80 0.412 1809 2913 Ni 8.80 0.90 0.439 1453 2709 Al 2.70 2.39 0.897 934 2238 Ti 4.51 0.22 0.523 1939 1396 表 3 国内外部分研究结果汇总表

Table 3. Summary of some research results at home and abroad

researchers experimental conditions experimental results

(electrode erosion rate)peak value

of discharge

current/kAquantity of charge

transferred by

single discharge/Celectrode

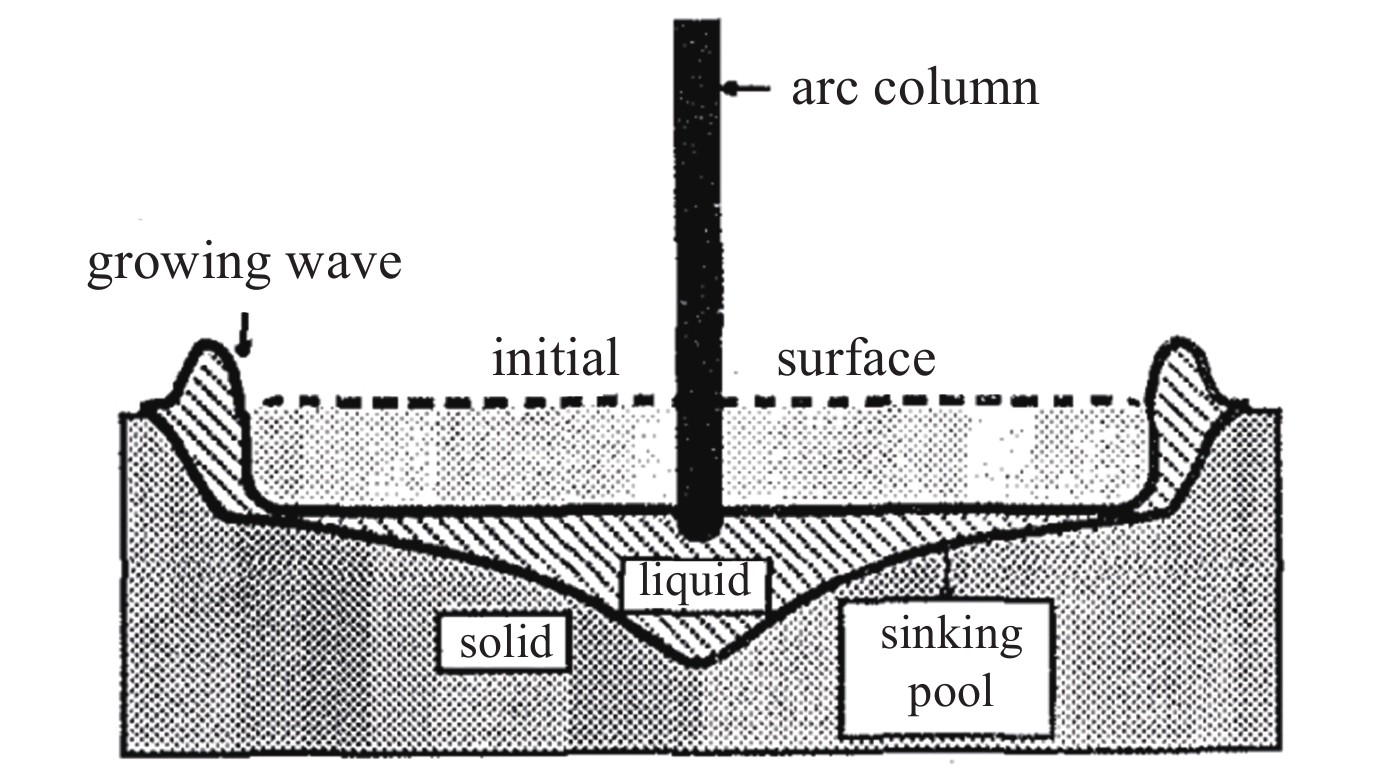

spacing/mmexperimental

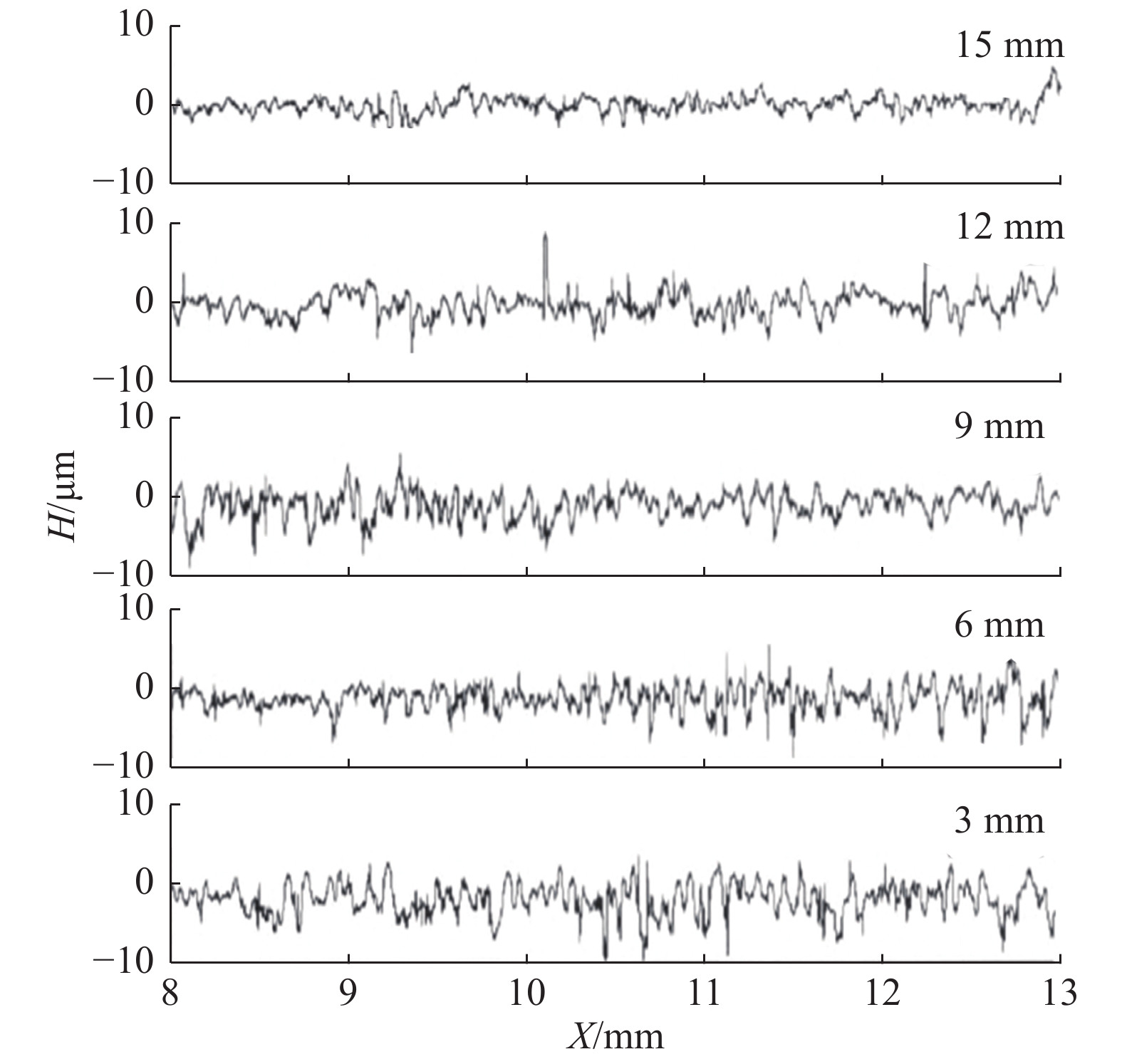

gasDonaldson et al[14] 240 3.85 10 open air Cu>Cu-Zr>Cu-Zr-Cr>Mo>CuC>

Cu-Mo>W-Cu>graphiteGordon et al[16] 30 0.03 SF6/N2 W-Cu>graphite Chen Weiqing et al[27] 100 0.28 20 SF6 brass>stainless steel>W-Cu>graphite Yao Xueling et al[28] 0.23 10.5 15 air 304 stainless steel>W-Cu>graphite Budin et al[33] 800 360 H2 Al>Fe>Mo>W>W-Ni-Cu Xie Changming et al[34] 3.2 0.025 4 N2 Mo>W-Cu>W Koutsoubis et al[35] 1 67.5 79%N2/21%O2 Al>brass>stainless Steel>W-Cu Liu Yu et al[36] 20.7 0.0154 15 N2 Cu>W-Cu>Mo>stainless steel Bai Feng et al[37] 20 0.3 4 air Al alloy>Ti alloy>Ti>stainless

steel>Cu-Zn>Mo>W-Cu -

[1] 刘锡三. 高功率脉冲功率技术[M]. 北京: 国防工业出版社, 2005.Liu Xisan. High pulsed power technology[M]. Beijing: National Defense Industry Press, 2005 [2] Bluhm H. 脉冲功率系统的原理与应用[M]. 北京: 清华大学出版社, 2008.Bluhm H. Pulsed power systems: principles and applications[M]. Beijing: Tsinghua University Press, 2008 [3] Li Xiaoang, Liu Xuandong, Gou Xuanqi, et al. Degradation of performance due to electrode erosion in field distortion gas switch in long-term repetitive operation[J]. IEEE Transactions on Plasma Science, 2014, 42(10): 3064-3069. doi: 10.1109/TPS.2014.2313636 [4] 李晓昂, 刘轩东, 曾凡辉, 等. 电极熔蚀导致的气体开关绝缘子性能劣化[J]. 强激光与粒子束, 2016, 26:085004. (Li Xiaoang, Liu Xuandong, Zeng Fanhui, et al. Degradation of gas switch insulator due to electrode erosion[J]. High Power Laser and Particle Beams, 2016, 26: 085004 [5] Li Xiaoang, Liu Xuandong, Zeng Fanhui, et al. Ejection of electrode molten droplet and its effect on the degradation of insulator in gas spark switches[J]. IEEE Transactions on plasma science, 2015, 43(4): 1049-1053. doi: 10.1109/TPS.2015.2408607 [6] 谢昌明, 谈效华, 杜涛, 等. 大电流放电条件下气体火花开关电性能研究[J]. 高压电器, 2014, 50(12):36-40. (Xie Changming, Tan Xiaohua, Du Tao, et al. Investigation on electrical performances of gas spark gaps in high current discharge[J]. High Voltage Apparatus, 2014, 50(12): 36-40 [7] 刘轩东, 沈曦, 李晓昂, 等. 脉冲作用下气体火花开关电极熔蚀研究[J]. 高电压技术, 2017, 43(9):3070-3077. (Liu Xuandong, Shen Xi, Li Xiaoang, et al. Researches on electrode erosion of gas spark switch under pulsed current[J]. High Voltage Engineering, 2017, 43(9): 3070-3077 [8] Zingerman A S. The effect of thermal conductivity upon the electrical erosion of metals[J]. Soviet Physics—technical Physics, 1956, 1(9): 1945-1958. [9] Donaldson A L. Electrode erosion in high-current, high-energy transient arcs[D]. Lubbock, USA: Texas Tech University, 1991. [10] Donaldson A L, Kristiansen M. Electrode erosion as a function of electrode materials in high current, high energy transient arcs[C]//Monterey: Pulsed Power Conference, 1989: 83-86. [11] Belkin G S. Dependence of electrode erosion on heat flux and duration of current flow[J]. Soviet Physics Technical Physics-Ussr, 1971, 15(7): 1167-1170. [12] Zingerman A S. The effect of thermal conductivity upon the electrical erosion of metals[J]. Soviet Physics—Technical Physics, 1956, 1(9): 1945-1958. [13] Zingerman A S. The role of Joule-Lenz heat effect in the electrical erosion of metals[J]. Zhurnal Tekhnicheskoi Fiziki, 1955, 25(11): 1931-1943. [14] DonaldsonA L, Kristiansn M, Watson A, et al. Electrode erosion in high current, high energy transient arcs[J]. IEEE Transactions on Magnetics, 1986, 22(6): 1441-1447. doi: 10.1109/TMAG.1986.1064638 [15] 王虎. 三电极场畸变气体火花开关电极烧蚀特性及寿命预测[D]. 西安: 西安交通大学, 2011.Wang Hu. Electrode erosion characteristics and failure prediction of three-electrode field distortion gas spark switch[D]. Xi’an: Xi’an Jiaotong University, 2011 [16] Gordon L B, Kristiansen M, Hagler M O, et al. Material studies in a high energy spark gap[J]. IEEE Transactions on Plasma Science, 1983, 10(4): 286-293. [17] Behrisch R. Surface erosion from plasma materials interaction[J]. Journal of Nuclear Materials, 1979, 85/86: 1047-1061. doi: 10.1016/0022-3115(79)90399-4 [18] Watson A, Donaldson A L, Ikuta K, et al. Mechanism of electrode surface damage and material removal in high current discharges[J]. IEEE Transactions on Magnetics, 1986, 22(6): 1799-1803. doi: 10.1109/TMAG.1986.1064660 [19] 何孟兵, 贺臣, 李劲. 气体火花开关电极的烧蚀研究[J]. 高电压技术, 2004, 30(10):54-55. (He Mengbing, He Chen, Li Jin. Research on erosion of gas spark switch electrodes[J]. High Voltage Engineering, 2004, 30(10): 54-55 [20] Peters J, Yin F, Borges C F M, et al. Erosion mechanisms of hafnium cathodes at high current[J]. Journal of Physics D: Applied Physics, 2005, 38(11): 1781-1794. doi: 10.1088/0022-3727/38/11/019 [21] Lehr F M, Kristiansen M. Electrode erosion from high current moving arcs[J]. IEEE Transactions on Plasma Science, 1989, 17(5): 811-817. doi: 10.1109/27.41210 [22] Donaldson A L, Kristiansen M. Utilization of a thermal model to predict electrode erosion parameters of engineering importance[C]//IEEE Conference Record of the 1990 Nineteenth Power Modulator Symposium.1990: 265-269. [23] Cramer K, Roman W. Electrode design based in transient thermal analysis[J]. Mechanical Engineering, 1970, 92(5): 75-79. [24] Belkin G S, Kiselev V Y. Electrode erosion in pulsed high-current discharges[J]. Soviet physics Technical physics, 1966, 11(2): 280-286. [25] 罗敏, 江金生, 常安碧, 等. 高功率气体火花开关电极烧蚀机理研究[J]. 强激光与粒子束, 2004, 16(6):781-786. (Luo Min, Jiang Jinsheng, Chang Anbi, et al. Study on mechanism of electrode erosion of high-power gas spark gap switch[J]. High Power Laser and Particle Beams, 2004, 16(6): 781-786 [26] Wang H, Zhang Q, Wei J, et al. Research on erosion property of field-distortion gas switch electrode in nanosecond pulse[J]. IEEE Transactions on Plasma Science, 2012, 40(6): 1733-1742. doi: 10.1109/TPS.2012.2191162 [27] 陈维青, 曾正中, 邹丽丽, 等. 100 kA微秒级气体火花开关电极喷射现象研究[J]. 强激光与粒子束, 2004, 16(1):98-100. (Chen Weiqing, Zeng Zhengzhong, Zou Lili, et al. Selection of gas spark gaps electrode material under microsecond 100 kA current pulse[J]. High Power Laser and Particle Beams, 2004, 16(1): 98-100 [28] Yao Xueling, Zeng Zhengzhong, Chen Jinliang. Electrode erosion of a high energy impulse spark gap switch[J]. Plasma Science and Technology, 2006, 7(6): 3157. [29] 罗维熙, 黄涛, 曾江涛. 间隙长度对气体火花开关静态性能的影响[J]. 强激光与粒子束, 2013, 28(9):2466-2470. (Luo Weixi, Huang Tao, Zeng Jiangtao. Influence of gap length on gas spark switch static performance[J]. High Power Laser and Particle Beams, 2013, 28(9): 2466-2470 [30] 黄涛, 罗维熙, 丛培天, 等. 不同电流下气体开关电极烧蚀特性实验研究[J]. 强激光与粒子束, 2014, 26:045042. (Huang Tao, Luo Weixi, Con Peitian, et al. Experimental study on electrode erosion characteristics of spark gas switch under different current[J]. High Power Laser and Particle Beams, 2014, 26: 045042 doi: 10.3788/HPLPB20142604.45042 [31] Lide D R. Landge’s handbook of chemistry[M]. Boca Raton: CRC Press, 2004. [32] Nieh T G, Wadsworth J, Witenauer J P. Tungsten and its alloys[J]. Advanced Materials & Processer(USA), 1992, 142(3): 28-33. [33] Budin A V, Kolikov V A, Rutberg F G. Influence of the current magnitude and working gas temperature on electrode erosion in the discharge chambers of high-power pulsed plasmatrons[J]. Technical Physics, 2007, 52(8): 1011-1015. doi: 10.1134/S1063784207080087 [34] 谢昌明, 谈效华, 杜涛, 等. 气体火花开关电极烧蚀研究[J]. 强激光与粒子束, 2014, 26:015003. (Xie Changming, Tan Xiaohua, Du Tao, et al. Electrode erosion research of gas spark gap[J]. High Power Laser and Particle Beams, 2014, 26: 015003 doi: 10.3788/HPLPB20142601.15003 [35] Koutsoubis J M, Macgregor S J. Electrode erosion and lifetime performance of a high repetition rate, triggered, corona-stabilized switch in air[J]. Journal of Physics D: Applied Physics, 2000, 33(9): 1093-1103. doi: 10.1088/0022-3727/33/9/309 [36] 刘瑜, 陈林, 戴英敏, 等. LTD模块气体开关电极材料烧蚀性能实验[J]. 强激光与粒子束, 2014, 26:085005. (Liu Yu, Chen Lin, Dai Yingmin, et al. Electrode erosion performance test of LTD stage gas spark switches[J]. High Power Laser and Particle Beams, 2014, 26: 085005 doi: 10.3788/HPLPB20142608.85005 [37] 白峰, 邱毓昌, 姜惟. 气体火花开关电极材料的冲击电流侵蚀特性[J]. 电工技术学报, 2001, 16(4):76-79. (Bai Feng, Qiu Yuchang, Jiang Wei. Erosion characteristics of the electrodes used for gas spark gap[J]. Transactions of China Electrotechnical Society, 2001, 16(4): 76-79 [38] Wang B J, Saka N. Thermal analysis of electrode heating and melting due to a spark[J]. IEEE Transactions on Components, Hybrids, and Manufacturing, Technology, 1993, 16(4): 456-466. doi: 10.1109/33.237943 [39] Budin A V, Pinchuk M E, Kuznetsov V E, et al. The influence of the production technology of iron-copper composite alloy on its erosion properties in a high-current high-pressure arc[J]. Technical Physics Letters, 2014, 40(12): 1061-1064. doi: 10.1134/S1063785014120050 [40] Budin A V, Pinchuk M E, Kurakina N K. Erosion characteristics of copper-based composite electrodes in an electric arc of variable length with transverse gas blowing[J]. Technical Physics Letters, 2018, 44(9): 808-810. doi: 10.1134/S1063785018090171 [41] Liu Yiwen, Zhang Chengyu, Qiao Shengru, et al. Characteristics of arc erosion for Cu-C composite materials in air[J]. Modern Physics letters B, 2009, 23(27): 3281-3287. doi: 10.1142/S0217984909021314 [42] Li Lee, Ren Shuai, Dai Hongyu, et al. Effect of 100-nm Al2O3 particle inclusions on 100-kA pulsed arc erosion of W–Cu electrodes[J]. IEEE Transactions on Plasma Science, 2020, 48(1): 228-236. doi: 10.1109/TPS.2019.2958681 [43] 吴佳玮. 大电流钨镍铁合金两电极气体火花开关研究[D]. 西安: 西安交通大学, 2018.Wu Jiawei. Study on high-current two-electrode W-Ni-Fe alloy gas spark switch[D]. Xi’an: Xi’an Jiaotong University, 2018 [44] 罗维熙, 丛培天, 孙铁平, 等. 电极材料对气体火花开关静态性能的影响[J]. 强激光与粒子束, 2016, 28:015022. (Luo Weixi, Cong Peitian, Sun Tieping, et al. Influence of electrode materials on static performance of gas spark switch[J]. High Power Laser and Particle Beams, 2016, 28: 015022 -

下载:

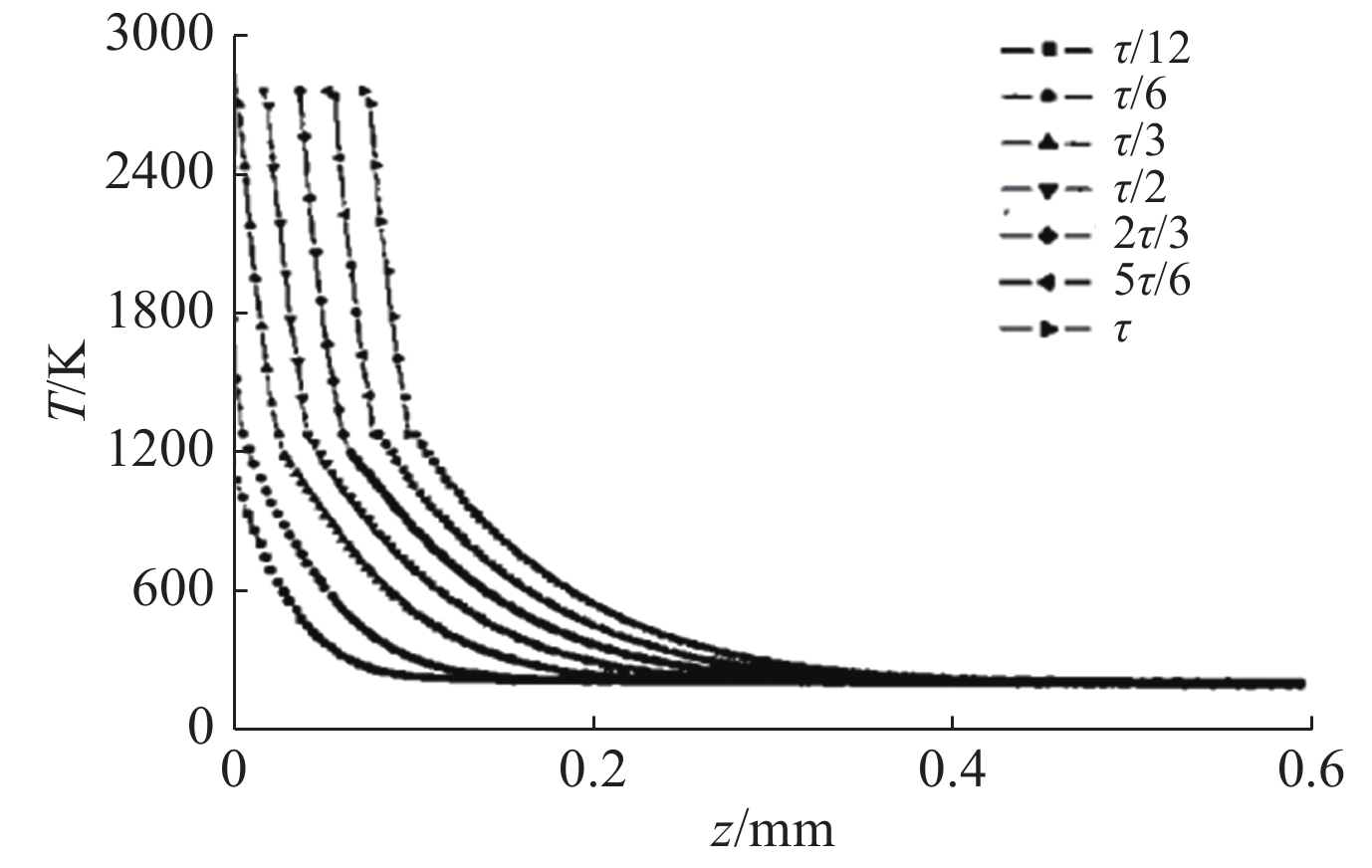

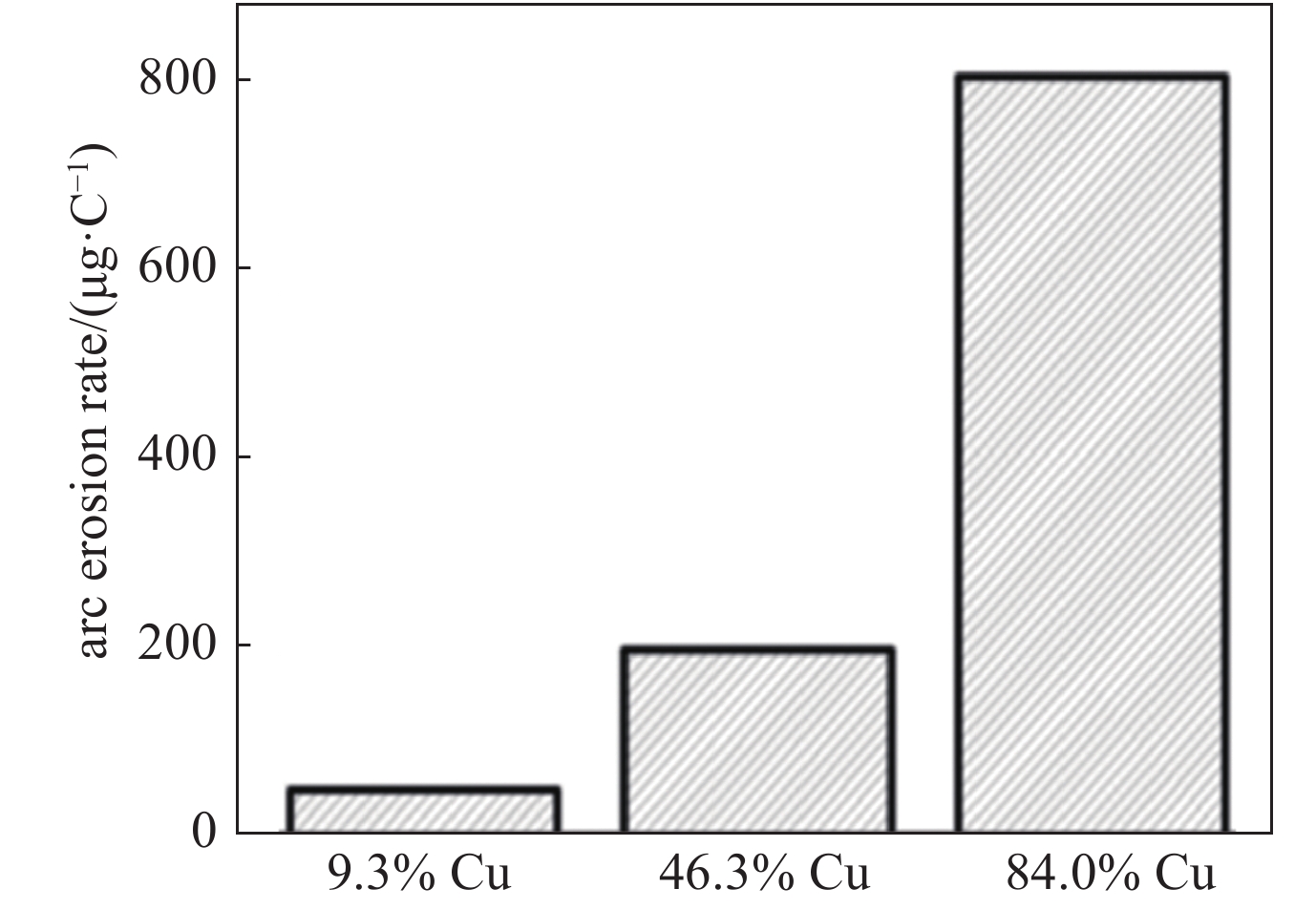

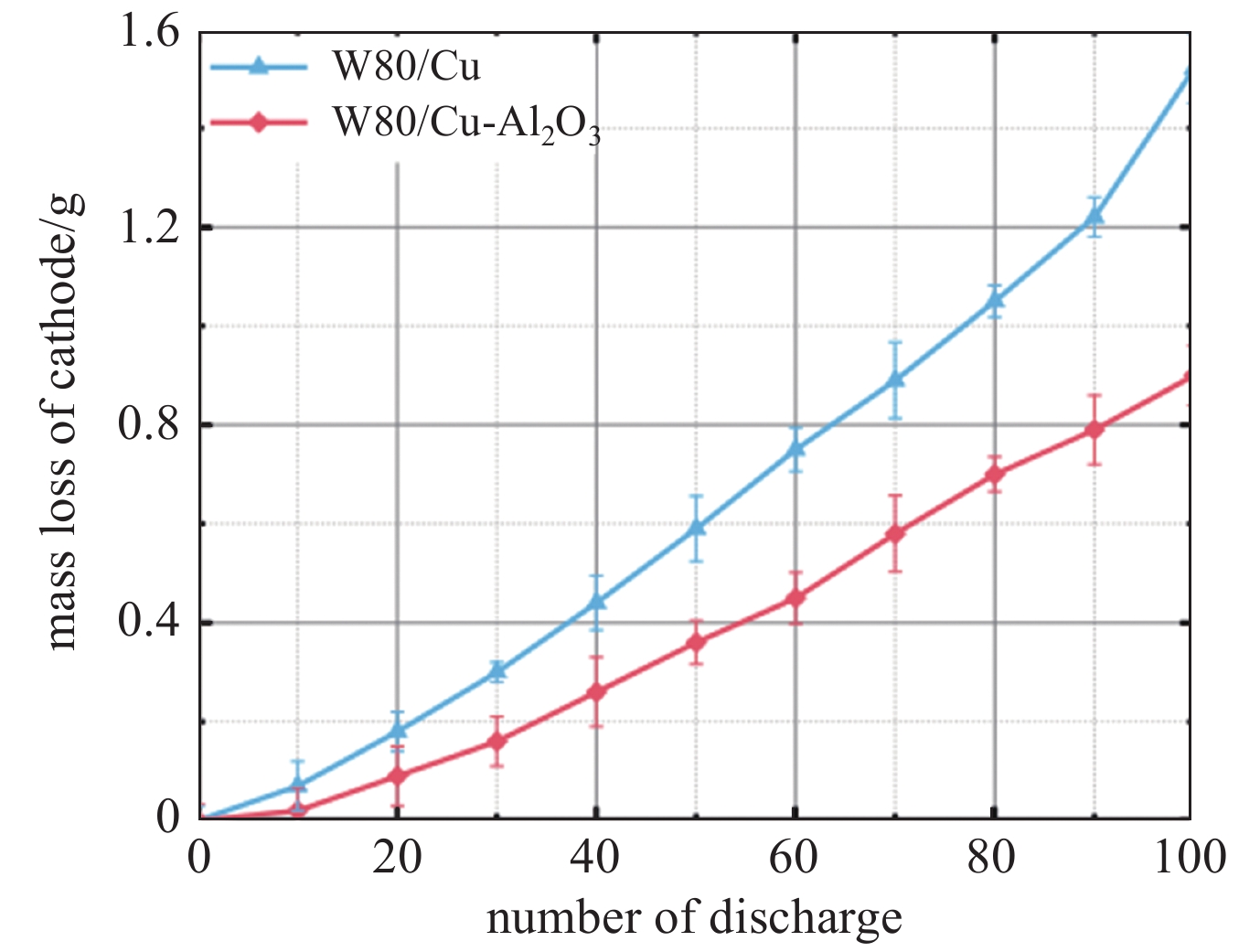

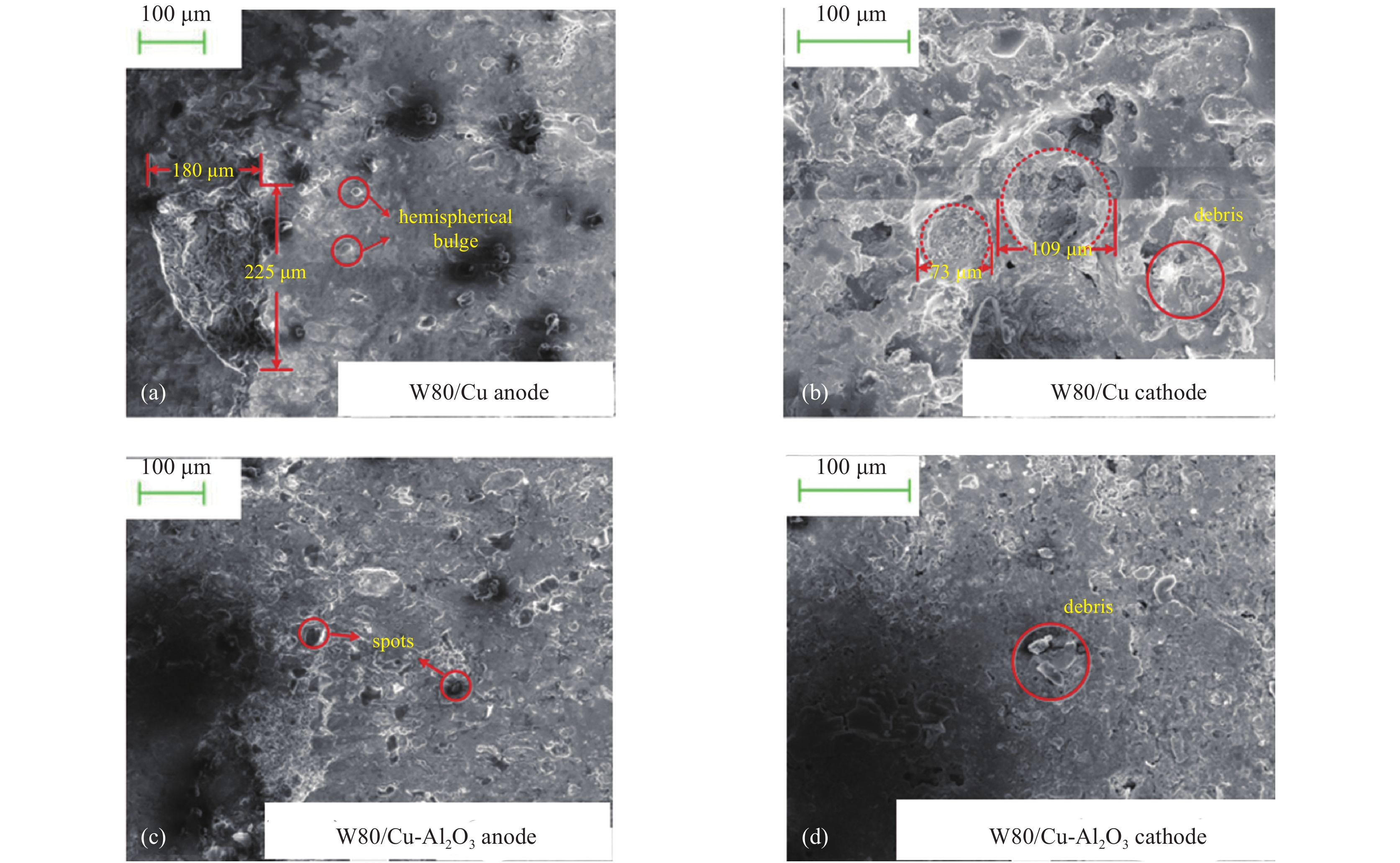

下载: