Error analysis of incoherent imaging binocular vision system

-

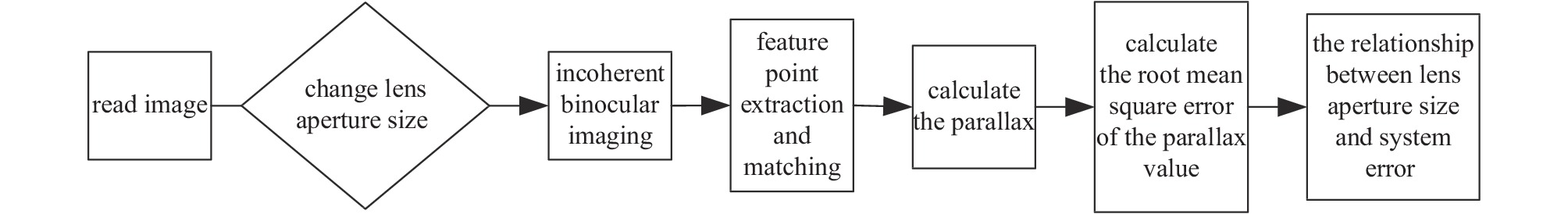

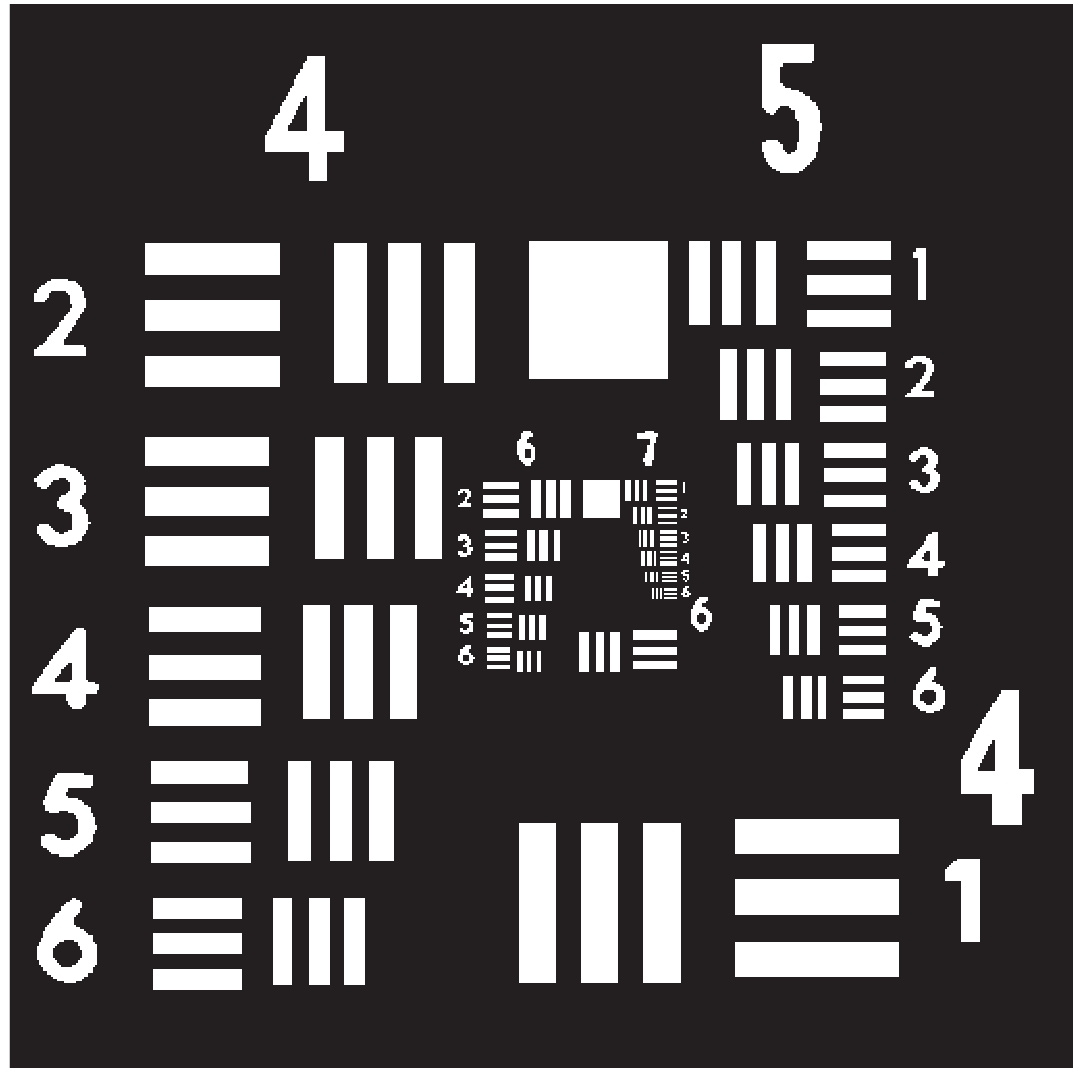

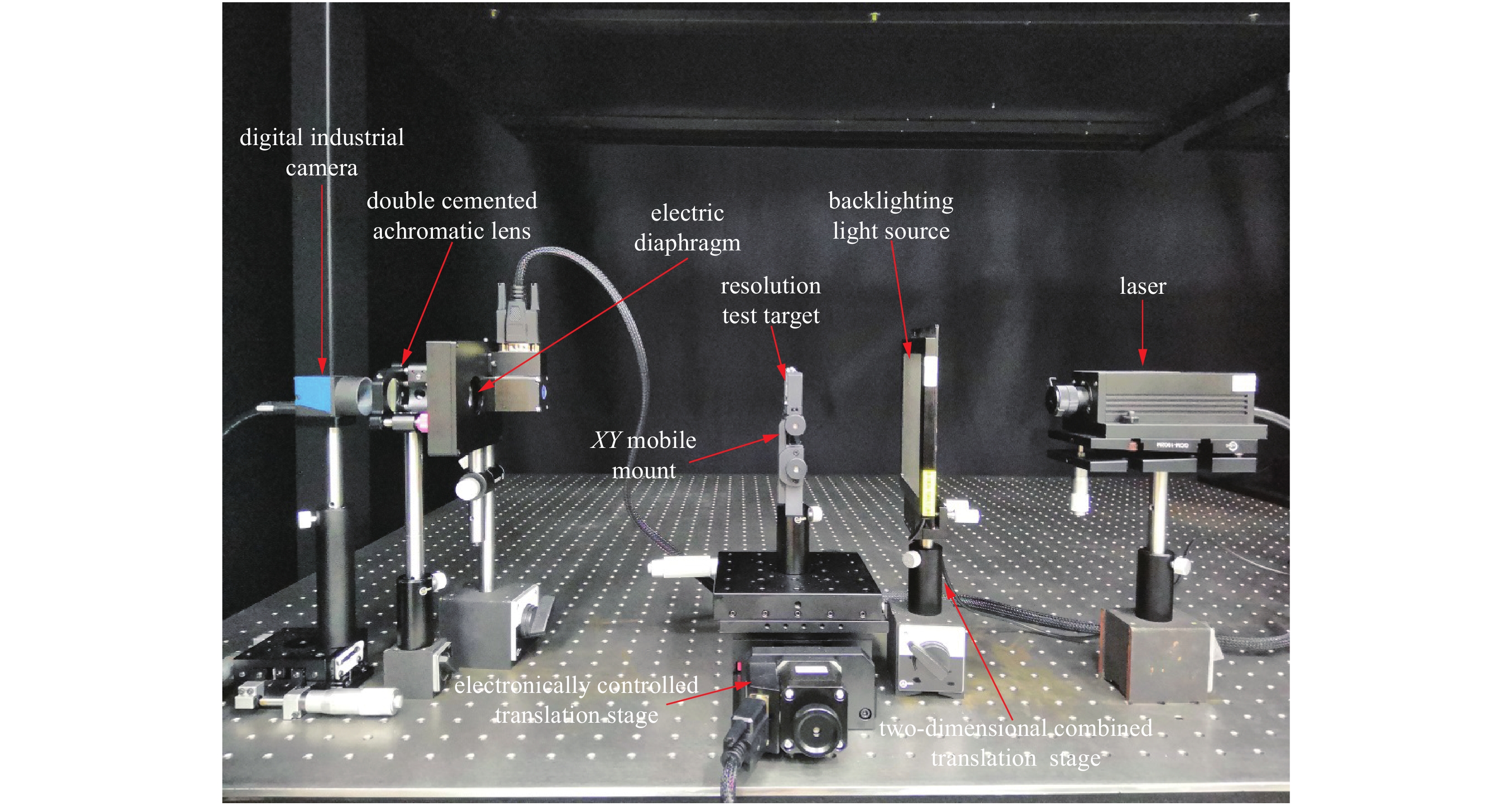

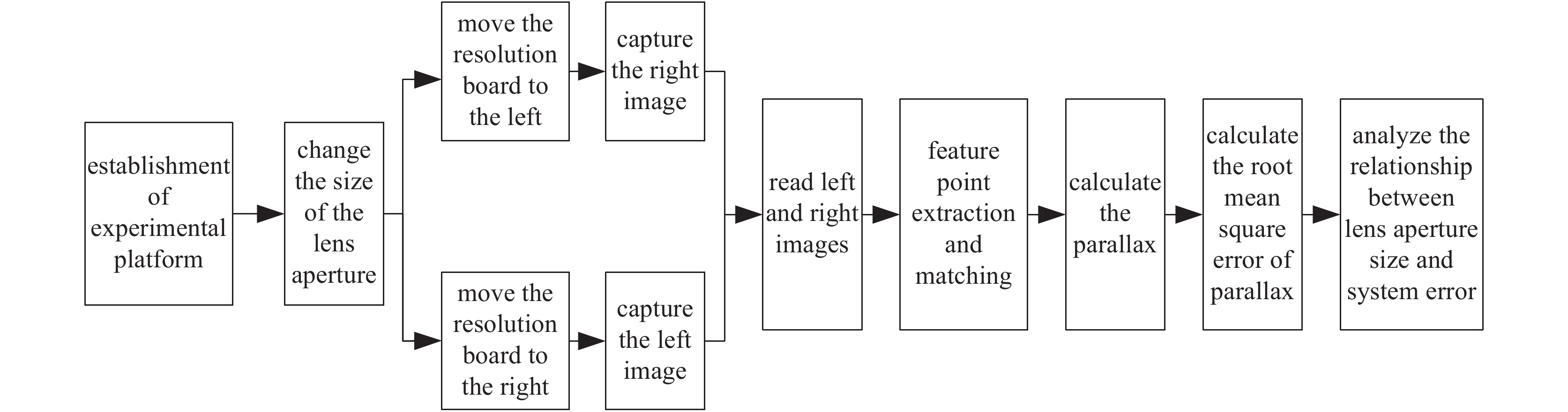

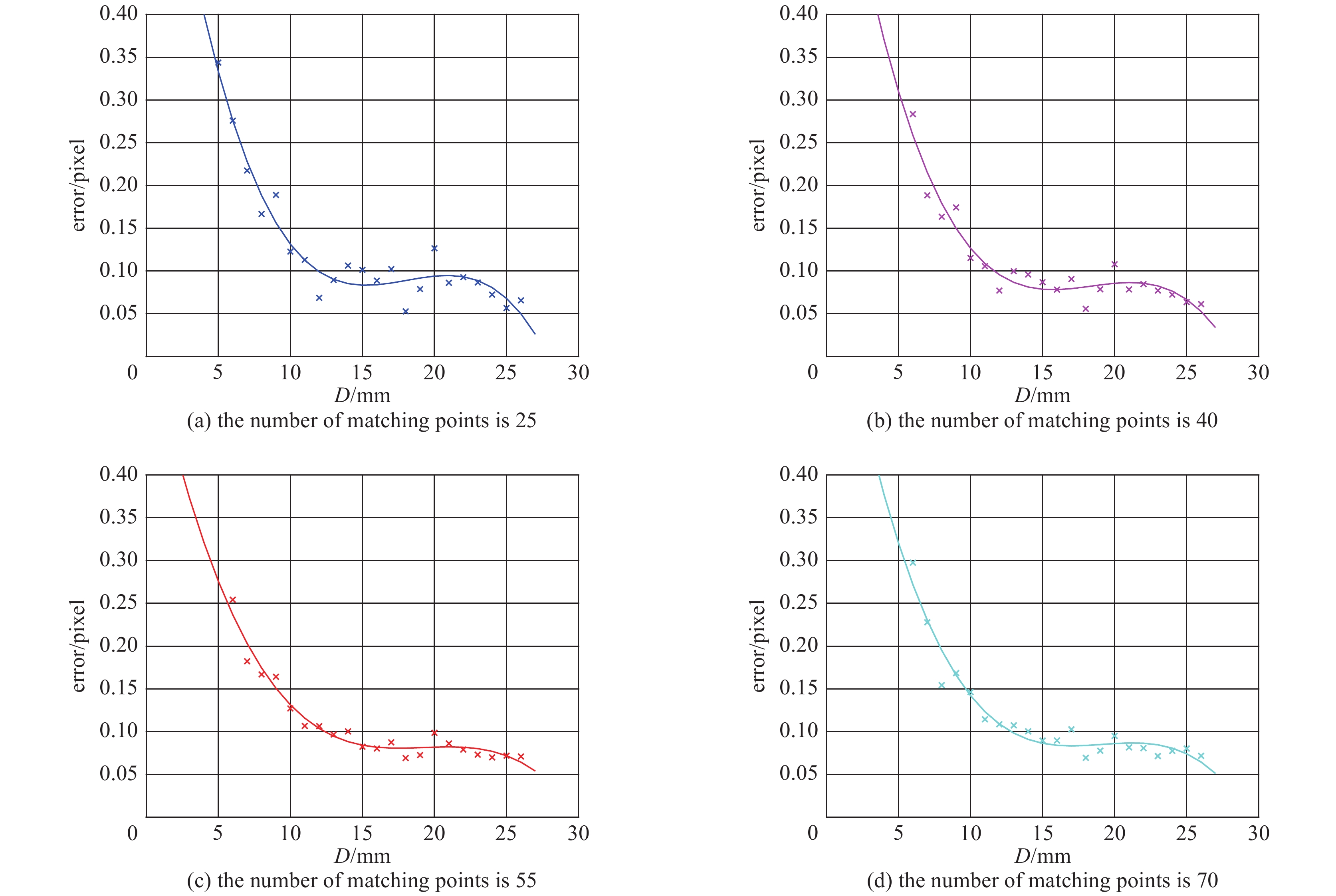

摘要: 影响双目视觉系统测量精度的因素很多,目前系统结构参数对测量精度的影响主要有光轴与基线的夹角、基线距离、水平视角、物距以及透镜焦距等。由于孔径尺寸直接影响成像分辨率,是决定双目视觉测量精度的核心因素,因此依据非相干成像理论,对双目成像过程进行仿真和实验,采用加速鲁棒特征算法对所成的图像对进行特征提取与匹配,获取其视差值,并且计算其视差均方根误差来表征系统误差。研究结果表明,系统误差随着透镜孔径大小的增大而减小,并且趋于饱和。该研究可以为双目系统设计过程中系统参数和孔径尺寸的选取提供理论和实验依据。Abstract: There are many factors that affect the measurement accuracy of binocular vision system. Currently, the influence of system structure parameters on the measurement accuracy mainly includes the angle between optical axis and baseline, baseline distance, horizontal viewing angle, object distance and lens focal length. Since the aperture size directly affect the imaging resolution, it is the core factor that determines the accuracy of binocular vision measurement. Consequently, according to the incoherent imaging theory, the binocular imaging process is simulated and tested. Moreover, Speeded Up Robust Features algorithm is adopted to extract and match the features of the image pairs to obtain their parallax values. The parallax root mean square error is calculated to represent the systematic errors. The results show that the system error decreases with the increase of lens aperture, and approaches saturation. This research can provide theoretical and experimental basis for the selection of system parameters and aperture size during the design of the binocular system.

-

表 1 实验仪器的相关参数

Table 1. Relevant parameters of the experimental instrument

laboratory apparatus parameter values digital industrial camera resolution: 3840×2748; pixel size: 1.67 μm×1.67 μm double cemented achromatic lens diameter: ϕ25.4 mm; focal length: 30 mm electric diaphragm diameter range: ϕ2.5~28 mm electronically controlled translation stage moving direction: x; reading accuracy: 0.001 mm two-dimensional combined translation stage moving direction: x-y; reading accuracy: 0.001 mm XY mobile mount horizontal stroke: 50 mm; vertical stroke: 30 mm resolution test target size: 76.2 mm×25.4 mm backlighting light source power: 25 W; light source color: red laser wavelength: 532 nm; power: 50 mW -

[1] Liu Qiong, Qin Xiansheng, Yin Shenshun, et al. Structural parameters optimal design and accuracy analysis for binocular vision measure system[C]//Proceedings of the 2008 IEEE/ASME International Conference on Advanced Intelligent Mechatronics. 2008: 156-161. [2] Fan Xinfeng, Cheng Yuanzeng, Fu Qiang. Accuracy analysis and structure configuration of binocular vision system[C]//Proceedings of the 2015 3rd International Conference on Machinery, Materials and Information Technology Applications. 2015: 1427-1431. [3] 闵新力, 万德安, 张剑. CCD双目视觉测量系统结构参数设置的理论研究[J]. 机械设计与制造, 2001(3):54-56. (Min Xinli, Wan De’an, Zhang Jian. Theoretical study on setting structural parameters of CCD binocular vision measurement system[J]. Machinery Design & Manufacture, 2001(3): 54-56 doi: 10.3969/j.issn.1001-3997.2001.03.026 [4] 赵萍, 李永奎, 田素博, 等. 双目视觉测量系统结构参数理论与试验研究[J]. 机械设计, 2013, 30(2):64-68. (Zhao Ping, Li Yongkui, Tian Subo, et al. Theoretical and experimental research on structural parameters of binocular vision measuring system[J]. Journal of Machine Design, 2013, 30(2): 64-68 doi: 10.3969/j.issn.1001-2354.2013.02.015 [5] 肖志涛, 张文寅, 耿磊, 等. 双目视觉系统测量精度分析[J]. 光电工程, 2014, 41(2):6-11. (Xiao Zhitao, Zhang Wenyin, Geng Lei, et al. Accuracy analysis of binocular vision system[J]. Opto-Electronic Engineering, 2014, 41(2): 6-11 [6] Yu Huan, Xing Tingwen, Jia Xin. The analysis of measurement accuracy of the parallel binocular stereo vision system[C]//Proceedings of SPIE, 8th International Symposium on Advanced Optical Manufacturing and Testing Technologies: Optical Test, Measurement Technology, and Equipment. 2016: 96841I. [7] Yang Lu, Wang Baoqing, Zhang Ronghui, et al. Analysis on location accuracy for the binocular stereo vision system[J]. IEEE Photonics Journal, 2018, 10: 7800316. [8] 毕超, 郝雪, 鄂玛兰, 等. 基于误差模型的双目视觉系统测量精度分析[J]. 航空精密制造技术, 2020, 56(2):1-4,30. (Bi Chao, Hao Xue, E Malan, et al. Accuracy analysis of binocular vision system based on the measuring error model[J]. Aviation Precision Manufacturing Technology, 2020, 56(2): 1-4,30 doi: 10.3969/j.issn.1003-5451.2020.02.001 [9] Fooladgar F, Samavi S, Soroushmehr S M R, et al. Geometrical analysis of localization error in stereo vision systems[J]. IEEE Sensors Journal, 2013, 13(11): 4236-4246. doi: 10.1109/JSEN.2013.2264480 [10] Schreve K. How accurate can a stereovision measurement be?[C]//15th International Workshop on Research and Education in Mechatronics (REM). 2014: 1-7. [11] Zhang T, Boult T. Realistic stereo error models and finite optimal stereo baselines[C]//2011 IEEE Workshop on Applications of Computer Vision (WACV). 2011: 426-433. [12] Wenhardt S, Denzler J, Niemann H. On minimizing errors in 3D reconstruction for stereo camera systems[J]. Pattern Recognition and Image Analysis, 2007, 17(2): 337-348. doi: 10.1134/S1054661807020228 [13] 闫锋涛, 范斌, 侯溪, 等. 稀疏子孔径采样检测大口径光学器件[J]. 强激光与粒子束, 2011, 23(12):3193-3196. (Yan Fengtao, Fan Bin, Hou Xi, et al. Large-aperture mirror test using sparse sub-aperture sampling[J]. High Power Laser and Particle Beams, 2011, 23(12): 3193-3196 doi: 10.3788/HPLPB20112312.3193 [14] 钱晓凡. 信息光学数字实验室(Matlab版)[M]. 北京: 科学出版社, 2015: 47-55Qian Xiaofan. Information optics digital laboratory (Matlab)[M]. Beijing: Science Press, 2015: 47-55) [15] 郁道银, 谈恒英. 工程光学[M]. 4版. 北京: 机械工业出版社, 2015: 457-459Yu Daoyin, Tan Hengying. Engineering optics[M]. 4th ed. Beijing: China Machine Press, 2015: 457-459) [16] 苏显渝. 信息光学[M]. 2版. 北京: 科学出版社, 2011: 63-66Su Xianyu. Information optics[M]. 2nd ed. Beijing: Science Press, 2011: 63-66) [17] Lowe D G. Distinctive image features from scale-invariant keypoints[J]. International Journal of Computer Vision, 2004, 60(2): 91-110. doi: 10.1023/B:VISI.0000029664.99615.94 [18] Bay H, Tuytelaars T, Van Gool L. SURF: speeded up robust features[J]. Computer Vision & Image Understanding, 2006, 110(3): 404-417. [19] Rublee E, Rabaud V, Konolige K, et al. ORB: an efficient alternative to SIFT or SURF[C]//2011 International Conference on Computer Vision. 2011: 2564-2571. [20] Karami E, Prasad S, Shehata M. Image matching using SIFT, SURF, BRIEF and ORB: performance comparison for distorted images[C]//2015 Newfoundland Electrical and Computer Engineering Conference. 2015: 1710-1714. [21] Wang Wei, Li Wenhui, Wang Chengxi, et al. A novel watermarking algorithm based on SURF and SVD[J]. Applied Mechanics and Materials, 2013, 303/306: 2117-2121. doi: 10.4028/www.scientific.net/AMM.303-306.2117 [22] 李建军, 史春梅, 单琪凯, 等. 基于SURF算法的大豆灰斑病视觉识别系统[J]. 大豆科学, 2019, 38(1):90-96. (Li Jianjun, Shi Chunmei, Shan Qikai, et al. Visual identification system of soybean frogeye leaf spot based on SURF feature extraction[J]. Soybean Science, 2019, 38(1): 90-96 [23] 徐明, 刁燕. 基于SURF算子与FLANN搜索的图像匹配方法研究[J]. 现代计算机, 2020(14):49-52,57. (Xu Ming, Diao Yan. Image matching method based on SURF Operator and FLANN search[J]. Modern Computer, 2020(14): 49-52,57 doi: 10.3969/j.issn.1007-1423.2020.14.011 [24] Li Aomei, Jiang Wanli, Yuan Weihua, et al. An improved FAST+SURF fast matching algorithm[C]//7th International Congress of Information and Communication Technology. 2017: 306-312. [25] 朱玲莹, 桑庆兵, 顾婷婷. 基于视差信息的无参考立体图像质量评价[J]. 计算机科学, 2020, 47(9):150-156. (Zhu Lingying, Sang Qingbing, Gu Tingting. No-reference stereo image quality assessment based on disparity information[J]. Computer Science, 2020, 47(9): 150-156 doi: 10.11896/jsjkx.190700213 -

下载:

下载: