Investigation on fast cooling method for pulsed magnet based on heat transfer of flowing liquid nitrogen in micro-channels

-

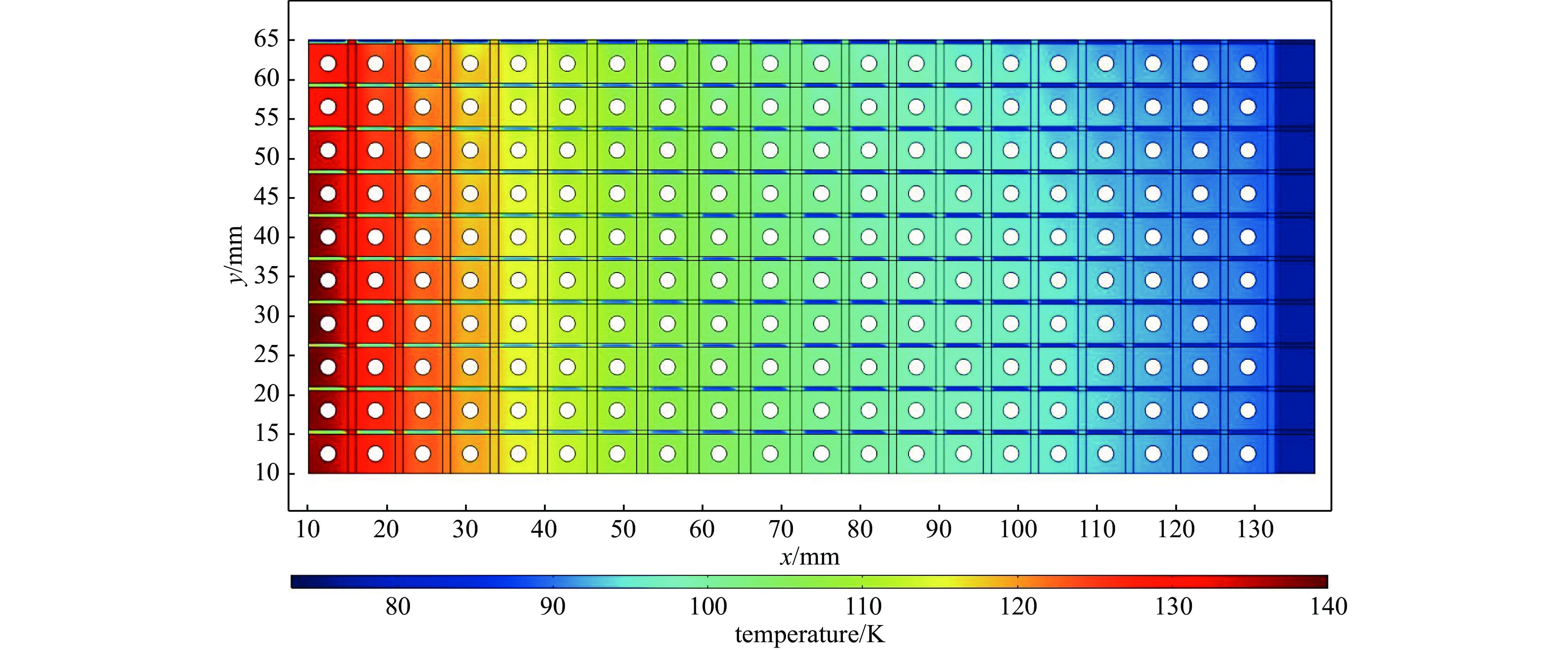

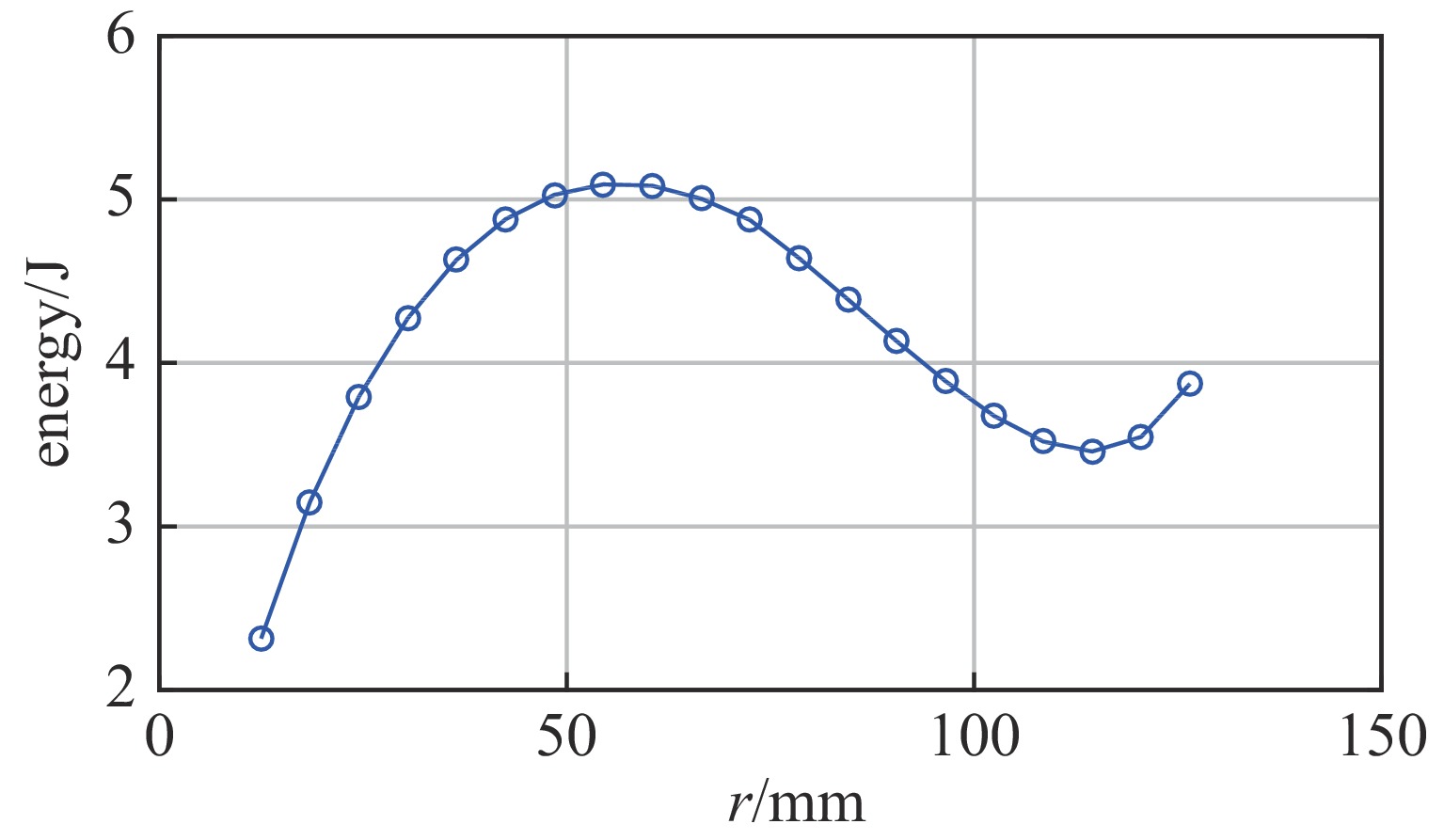

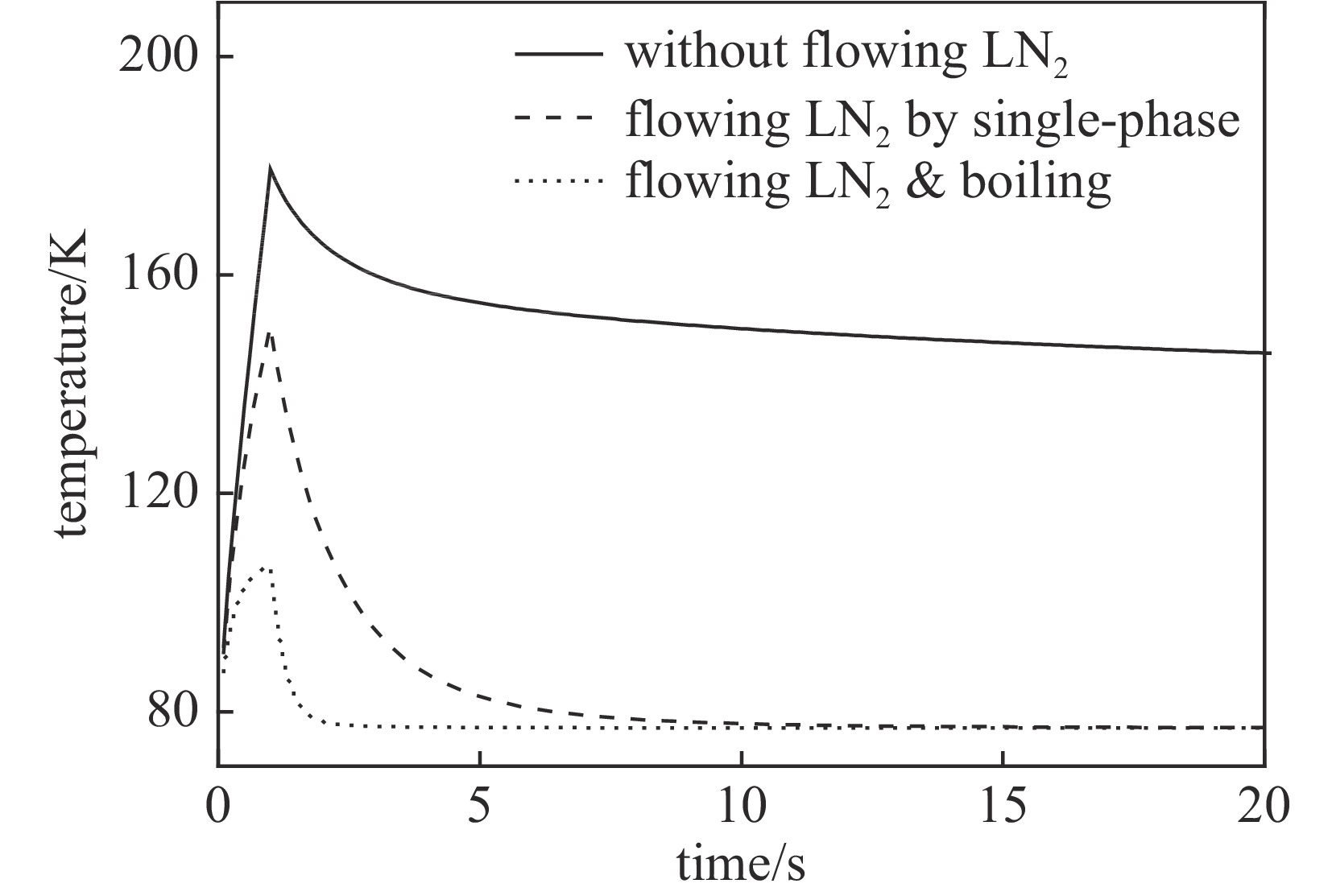

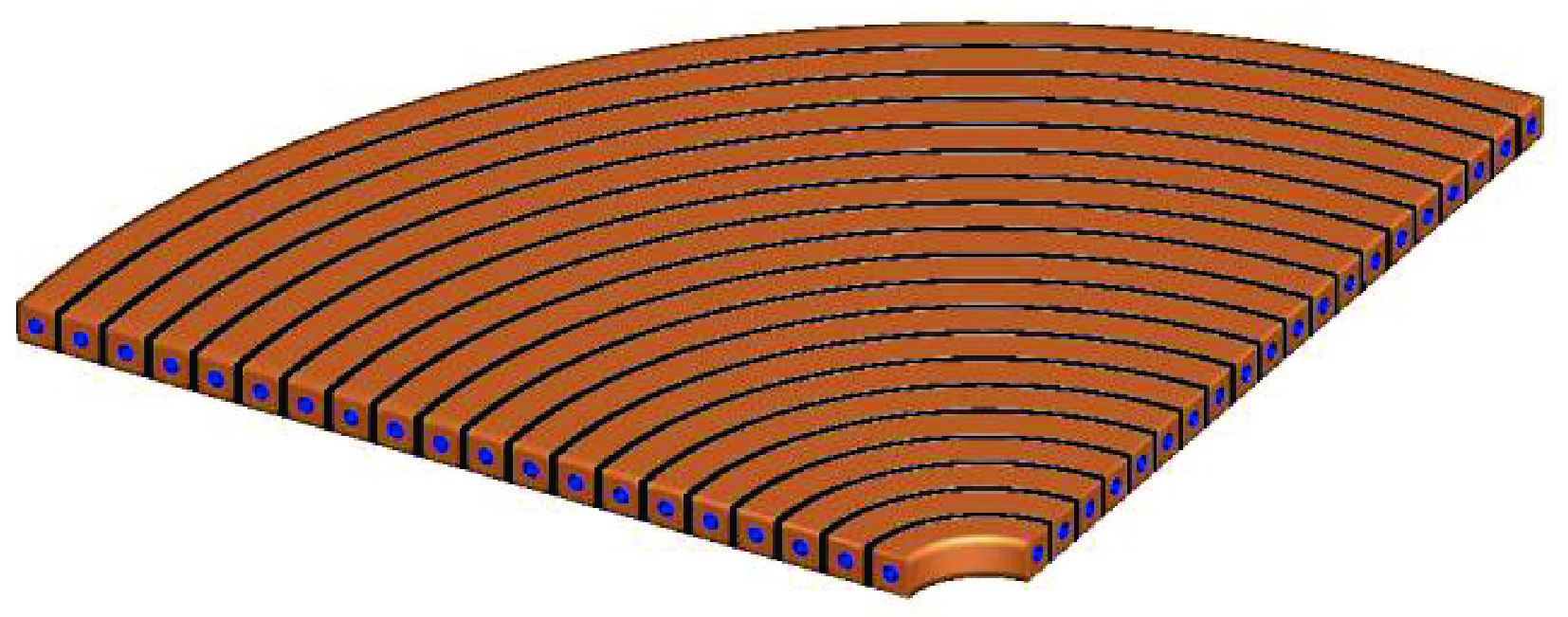

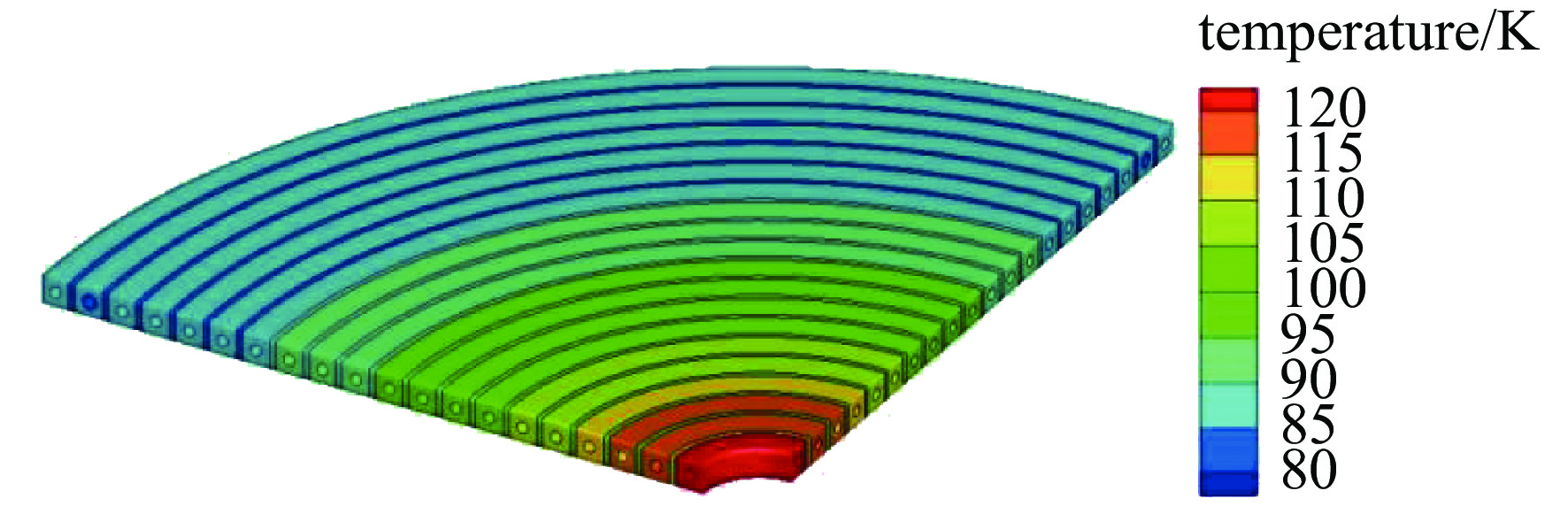

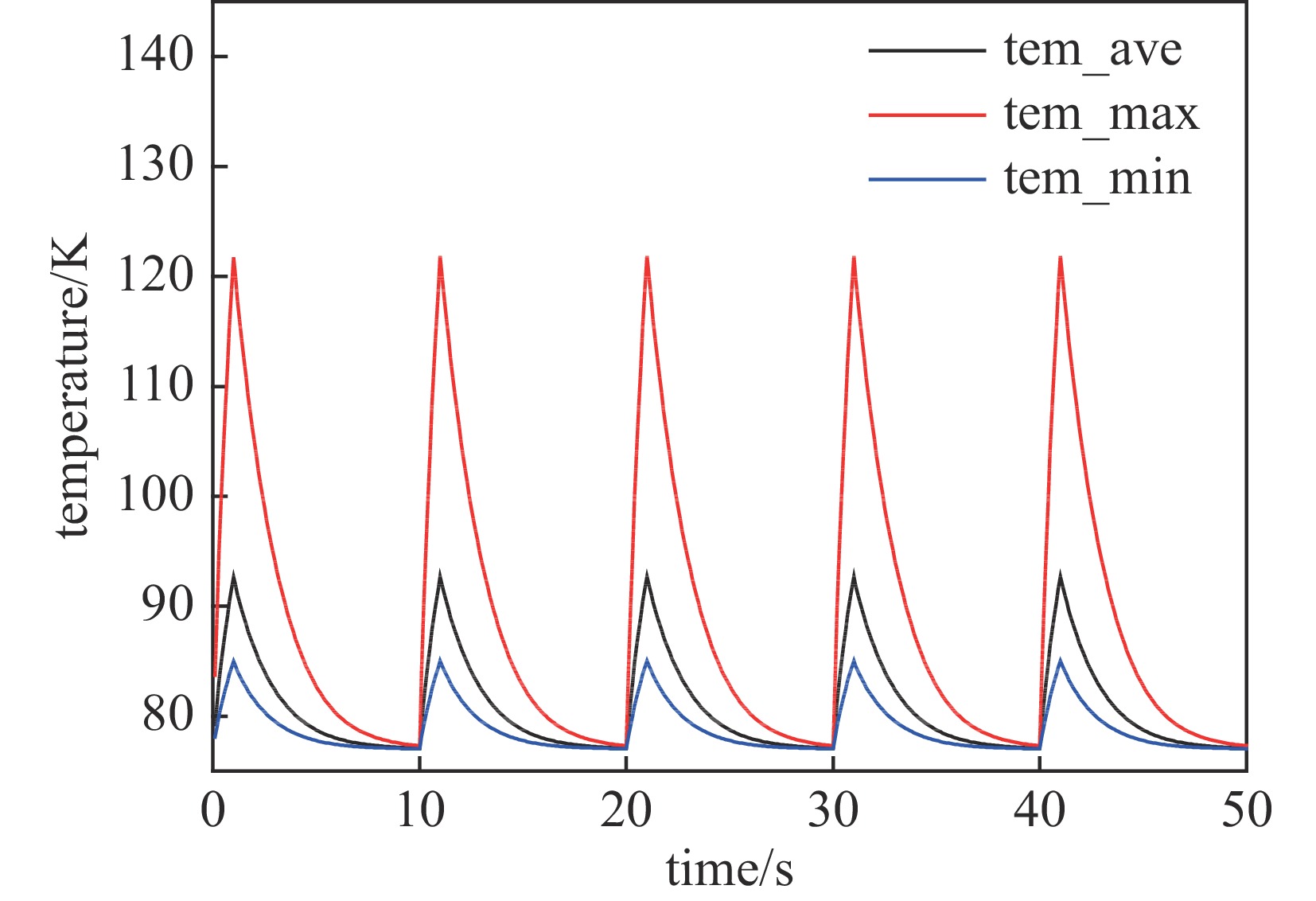

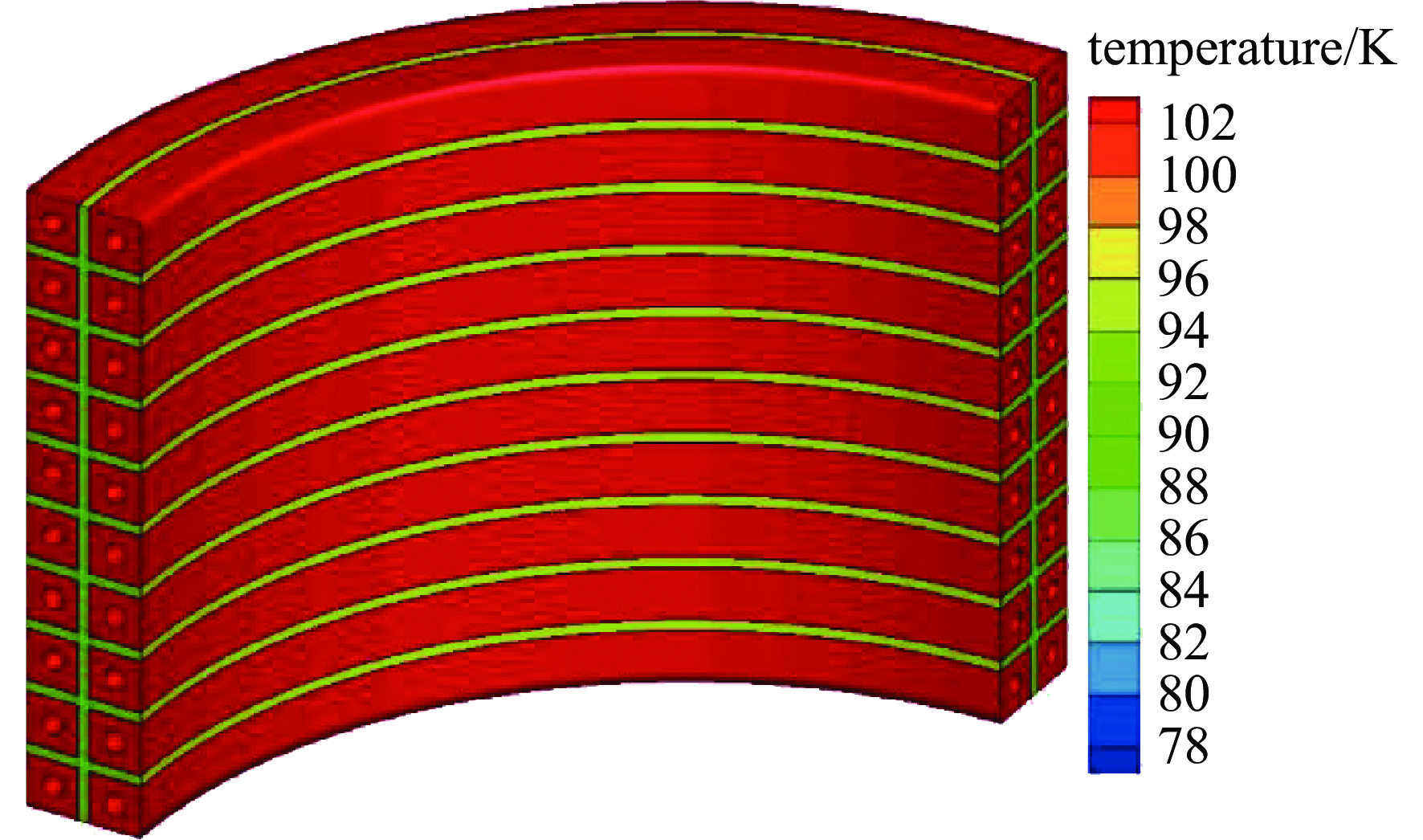

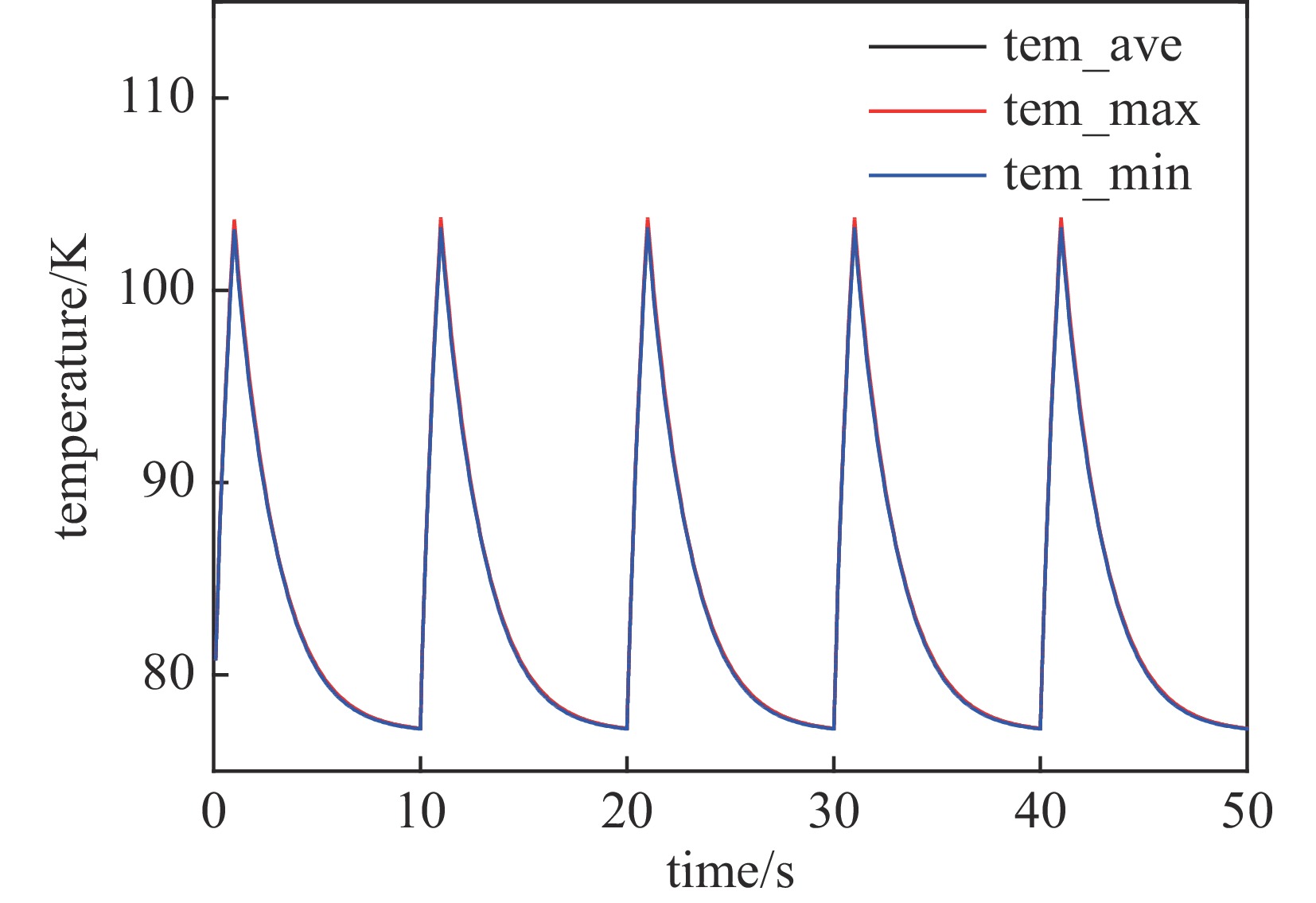

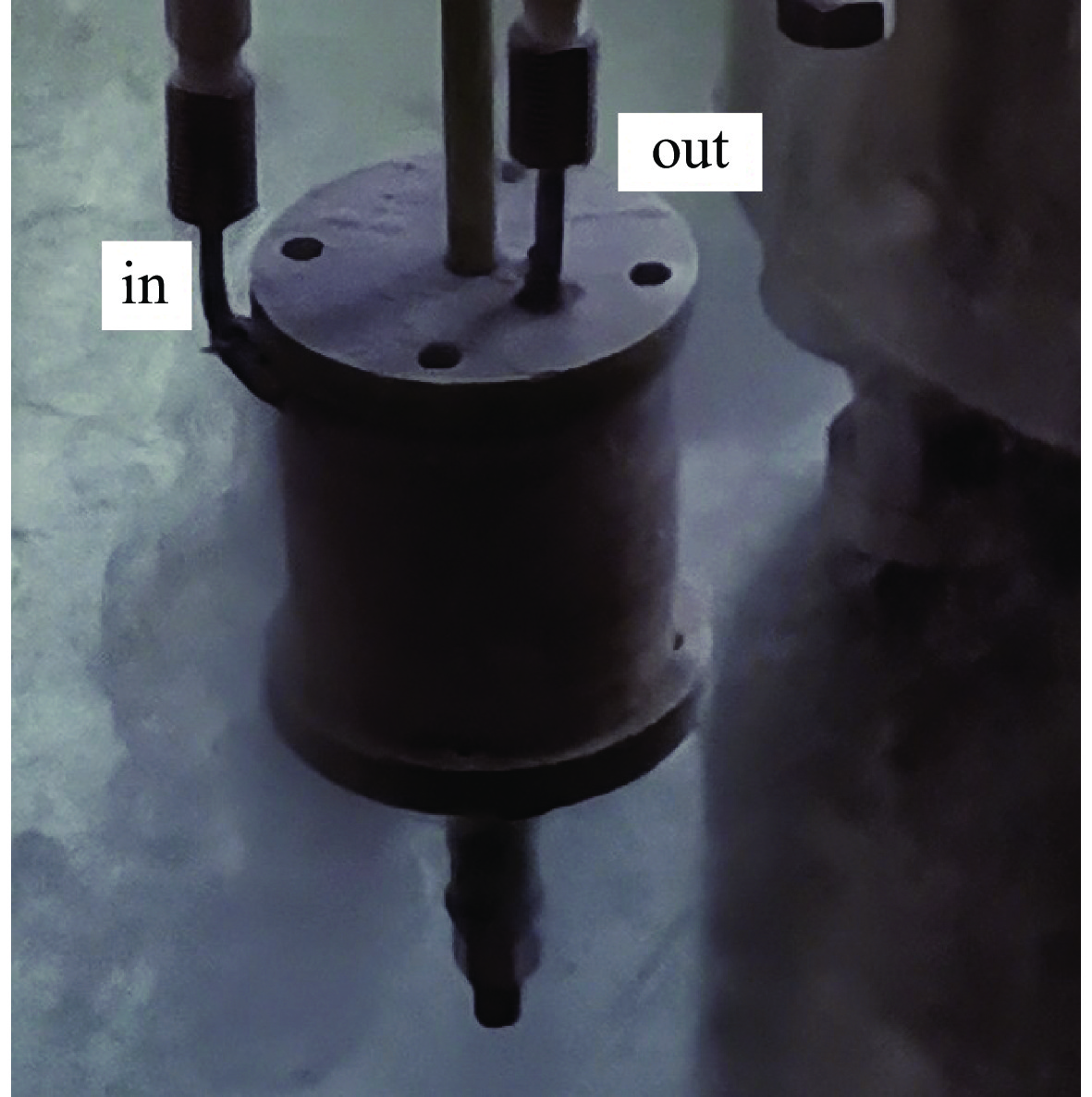

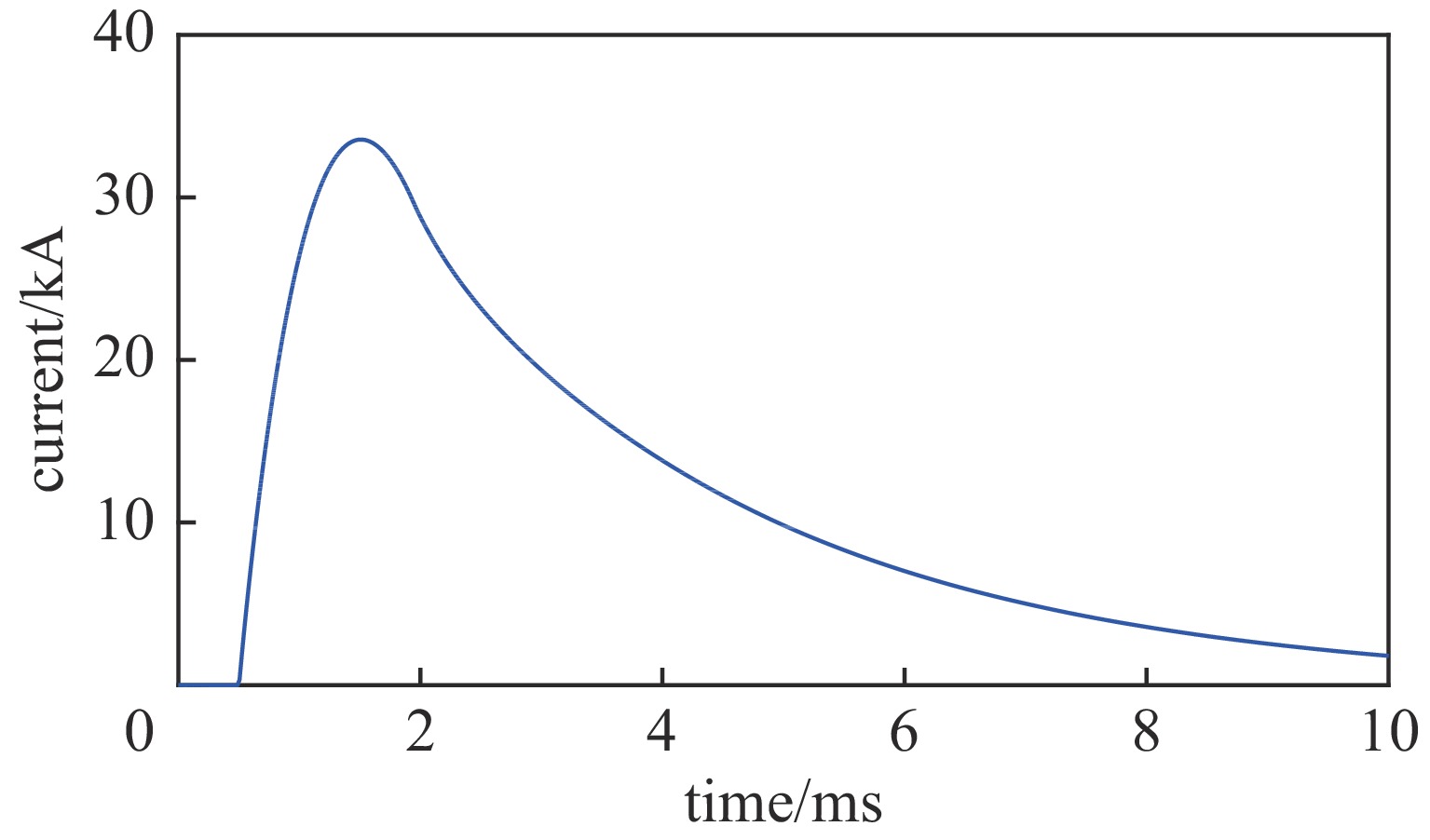

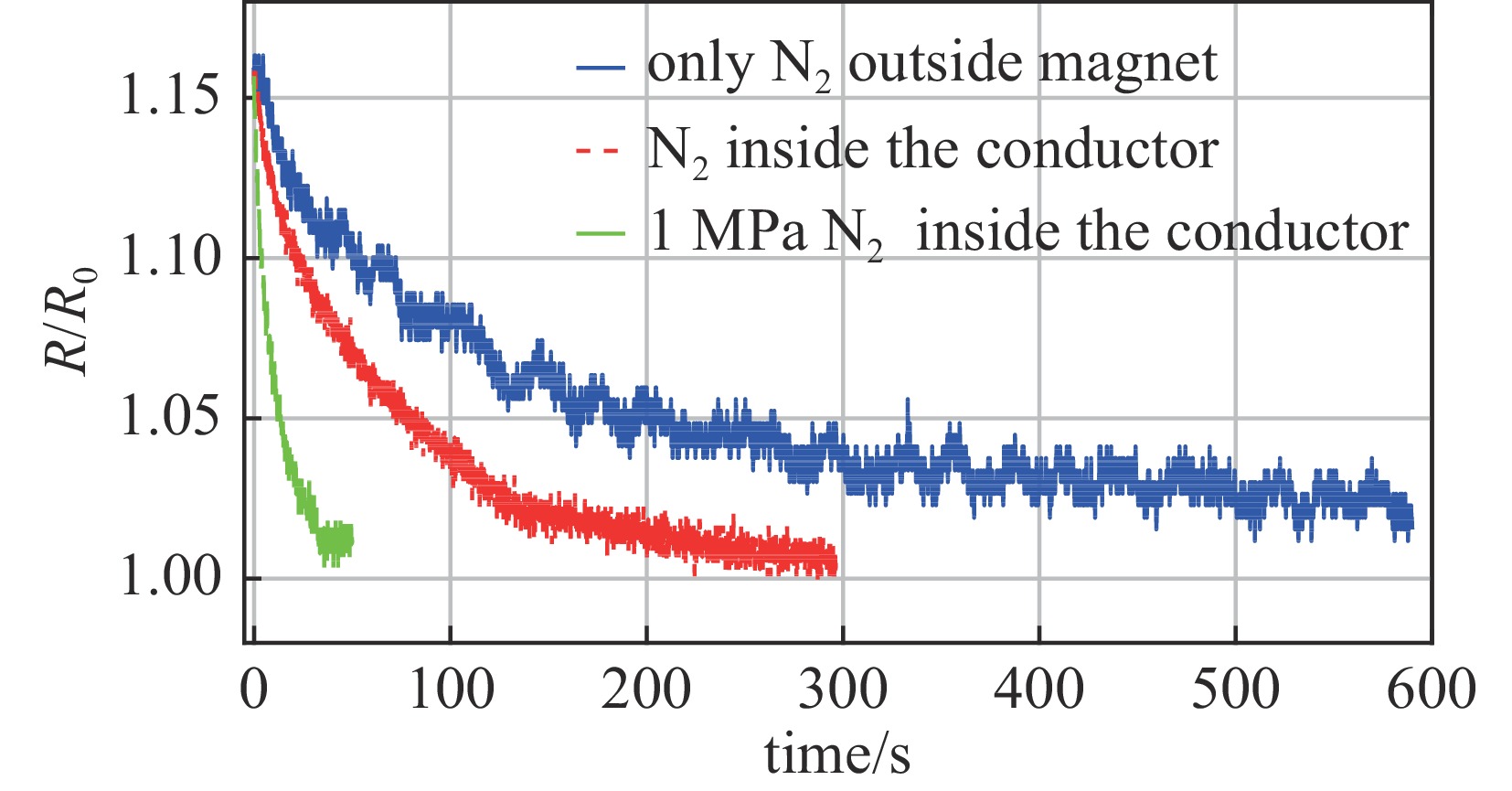

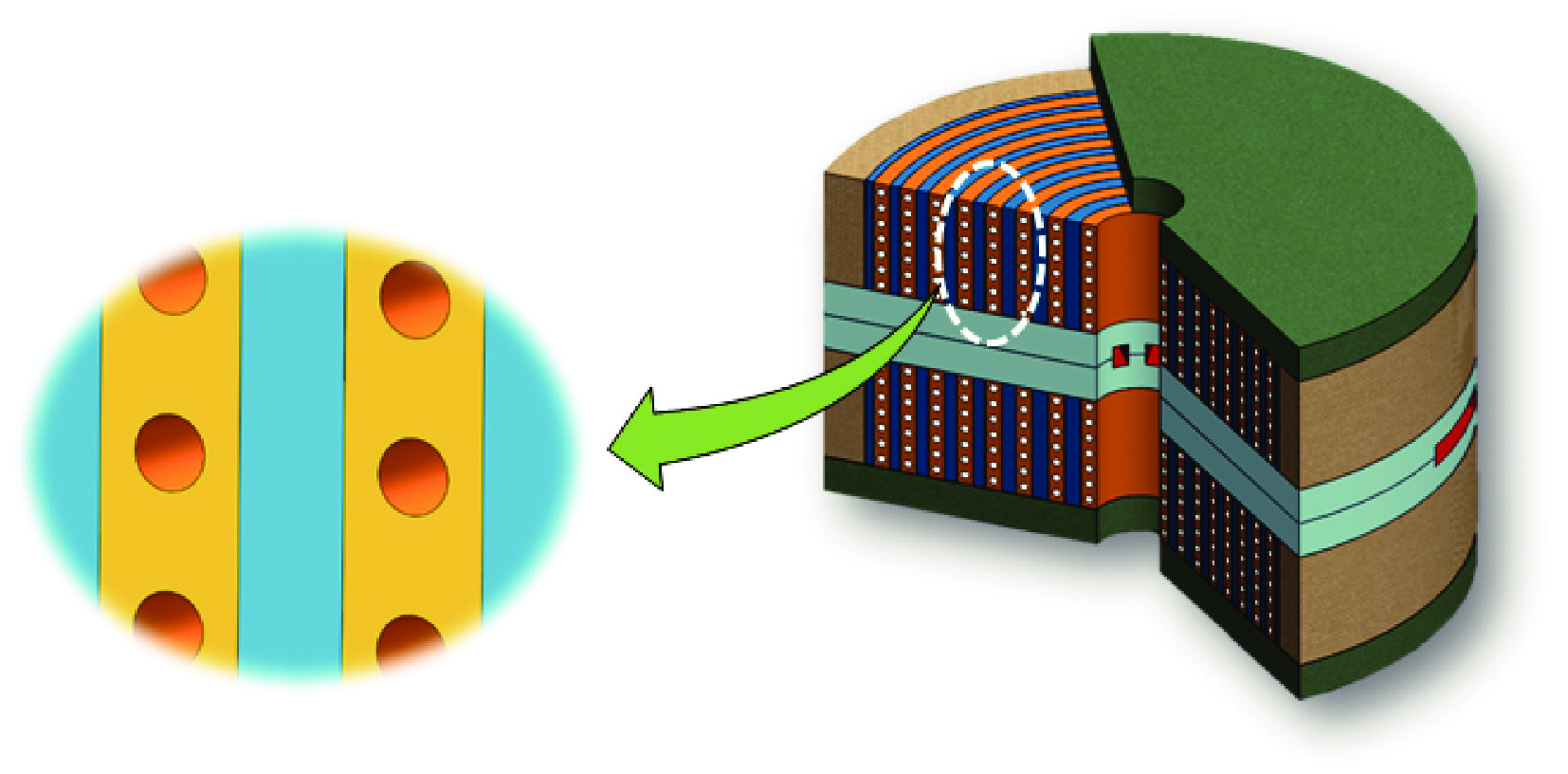

摘要: 影响脉冲磁体重频运行能力的关键因素是磁体的冷却速度。提出了一种脉冲磁体快速冷却方法:在磁体导体内开微小通道,在通道内注入液氮,通过增大导体与液氮之间的直接接触面积(换热面积)、液氮单相流动换热、液氮流动沸腾换热这三个途径来大幅提高导体的冷却速度,与此同时尽可能减小对脉冲磁体性能(磁场强度、脉宽和内直径)的影响。阐述了基于微通道内液氮流动、沸腾换热的脉冲磁体快速冷却方法的原理,开展了数值模拟和验证性试验,结果表明,对于25 T的20 mm口径脉冲磁体,采用快速冷却方法,30 s即可冷却至初始温度,为磁体仅浸泡在液氮中的冷却时间(600 s)的5%,冷却速度提高了19倍。Abstract: The cooling-down time limits the capability of repetitive operation of the pulsed magnet. A fast cooling method for the pulsed magnet based on heat transfer of flowing liquid nitrogen (LN2) in micro-channels formed inside the conductors of the pulsed magnet is presented. The large amount of heat produced during discharging of the pulsed magnet can be quickly dissipated by LN2 inside the micro-channels through the enlarged contact areas between LN2 and conductors, by single-phase LN2 flow and/or flow boiling. Furthermore, the impacts of the micro-channels on the performances (strengthening of the magnetic field, pulse duration and diameter of inner bore) can be tolerable. The principles of fast cooling method based on single-phase LN2 flow or flow boiling are elucidated. Numerical simulations and validation experiments of the fast cooling method indicate that pulsed magnet with inner bore diameter of 20 mm and magnetic field of 25 T can be cooled down in 30 s. The cooling speed of the pulsed magnet of the fast cooling method is increased by about 19 times compared with the conventional cooling method (600 s) where the pulsed magnet is simply immersed in LN2.

-

Key words:

- pulsed magnet /

- capability of repetitive operation /

- micro-channels /

- flow boiling /

- forced convection

-

表 1 铜和环氧树脂材料在不同温度下的热物性

Table 1. Thermal properties of copper and epoxy under different temperatures

thermal

property/Kdensity

of cooper/

(kg·m−3)specific heat

capacity of

cooper/(J·kg−1·K−1)thermal

conductivity of

cooper/(W·m−2·K−1)density of

composite

material/(kg·m−3)specific heat

capacity of composite

material/(J·kg−1·K−1)thermal conductivity

of composite

material/(W·m−2·K−1)95 8978 199.13 579.14 1560 246.40 0.22 77 8978 245.20 490.34 1560 304.00 0.29 135 8978 307.03 440.22 1560 432.00 -

[1] Noe II G T, Nojiri H, Lee J, et al. A table-top, repetitive pulsed magnet for nonlinear and ultrafast spectroscopy in high magnetic fields up to 30 T[J]. Review of Scientific Instruments, 2013, 84: 123906. doi: 10.1063/1.4850675 [2] Frings P, Witte H, Jones H, et al. Rapid cooling methods for pulsed magnets[J]. IEEE Transactions on Applied Superconductivity, 2008, 18(2): 612-615. doi: 10.1109/TASC.2008.921243 [3] Peng Tao, Sun Quqin, Zhao Jianlong, et al. Development of fast cooling pulsed magnets at the Wuhan National High Magnetic Field Center[J]. Review of Scientific Instruments, 2013, 84: 125112. doi: 10.1063/1.4849195 [4] 孙凤玉, 张鹏, 王如竹. 毛细管内液氮的自然对流换热数值计算分析[J]. 低温与超导, 2006, 34(2):79-84 doi: 10.3969/j.issn.1001-7100.2006.02.003Sun Fengyu, Zhang Peng, Wang Ruzhu. Numerical study of the natural convection heat transfer of liquid nitrogen in the capillary tubes[J]. Cryogenics, 2006, 34(2): 79-84 doi: 10.3969/j.issn.1001-7100.2006.02.003 [5] Steiner D, Schlünder E U. Heat transfer and pressure drop for boiling nitrogen flowing in a horizontal tube: 1. Saturated flow boiling[J]. Cryogenics, 1976, 16(7): 387-399. doi: 10.1016/0011-2275(76)90050-3 [6] Steiner D, Schlünder E U. Heat transfer and pressure drop for boiling nitrogen flowing in a horizontal tube: 2. Pressure drop[J]. Cryogenics, 1976, 16(8): 457-464. doi: 10.1016/0011-2275(76)90002-3 [7] Klimenko V V. Heat transfer intensity at forced flow boiling of cryogenic liquids in tubes[J]. Cryogenics, 1982, 22(11): 569-576. doi: 10.1016/0011-2275(82)90003-0 [8] Qi Shouliang, Zhang Pingang, Wang R Z, et al. Single-phase pressure drop and heat transfer characteristics of turbulent liquid nitrogen flow in micro-tubes[J]. International Journal of Heat and Mass Transfer, 2007, 50(9/10): 1993-2001. [9] Qi Shouliang, Zhang Pingang, Wang R Z, et al. Flow boiling of liquid nitrogen in micro-tubes: part I—the onset of nucleate boiling, two-phase flow instability and two-phase flow pressure drop[J]. International Journal of Heat and Mass Transfer, 2007, 50(25/26): 4999-5016. [10] Qi Shouliang, Zhang Pingang, Wang R Z, et al. Flow boiling of liquid nitrogen in micro-tubes: part II—heat transfer characteristics and critical heat flux[J]. International Journal of Heat and Mass Transfer, 2007, 50(25/26): 5017-5030. [11] Fu X, Qi Shouliang, Zhang Pingang, et al. Visualization of flow boiling of liquid nitrogen in a vertical mini-tube[J]. International Journal of Multiphase Flow, 2008, 34(4): 333-351. doi: 10.1016/j.ijmultiphaseflow.2007.10.014 [12] Zhang Pingang, Jia Hongwei. Evolution of flow patterns and the associated heat and mass transfer characteristics during flow boiling in mini-/micro-channels[J]. Chemical Engineering Journal, 2016, 306: 978-991. doi: 10.1016/j.cej.2016.08.034 [13] Billette J, Duc F, Frings P, et al. A 30 T pulsed magnet with conical bore for synchrotron powder diffraction[J]. Review of Scientific Instruments, 2012, 83: 043904. doi: 10.1063/1.3701830 [14] Islam Z, Capatina D, Ruff J P C, et al. A single-solenoid pulsed-magnet system for single-crystal scattering studies[J]. Review of Scientific Instruments, 2012, 83: 035101. doi: 10.1063/1.3688251 -

下载:

下载: