Design of the China Spallation Neutron Source phase II double spoke resonator

-

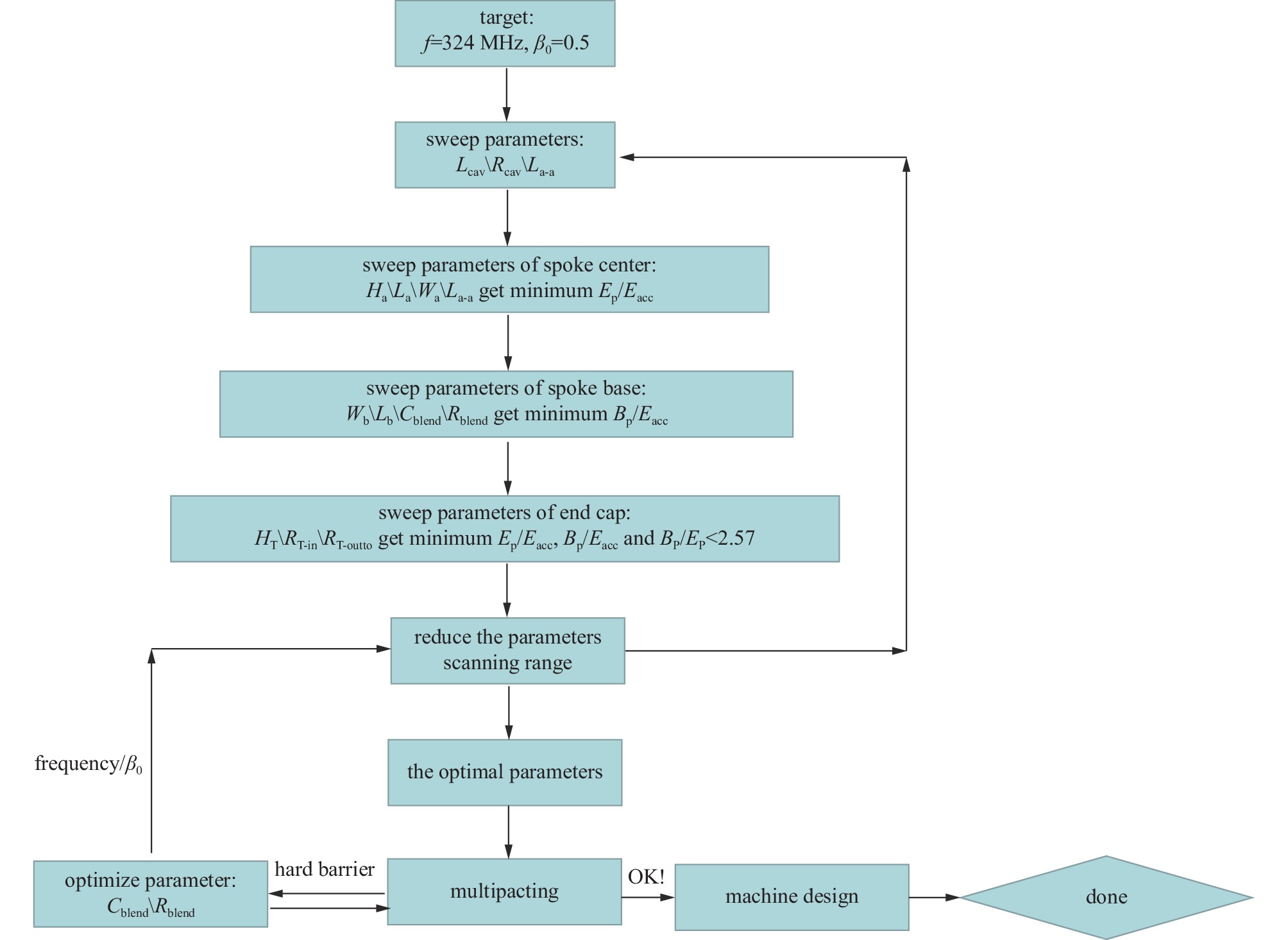

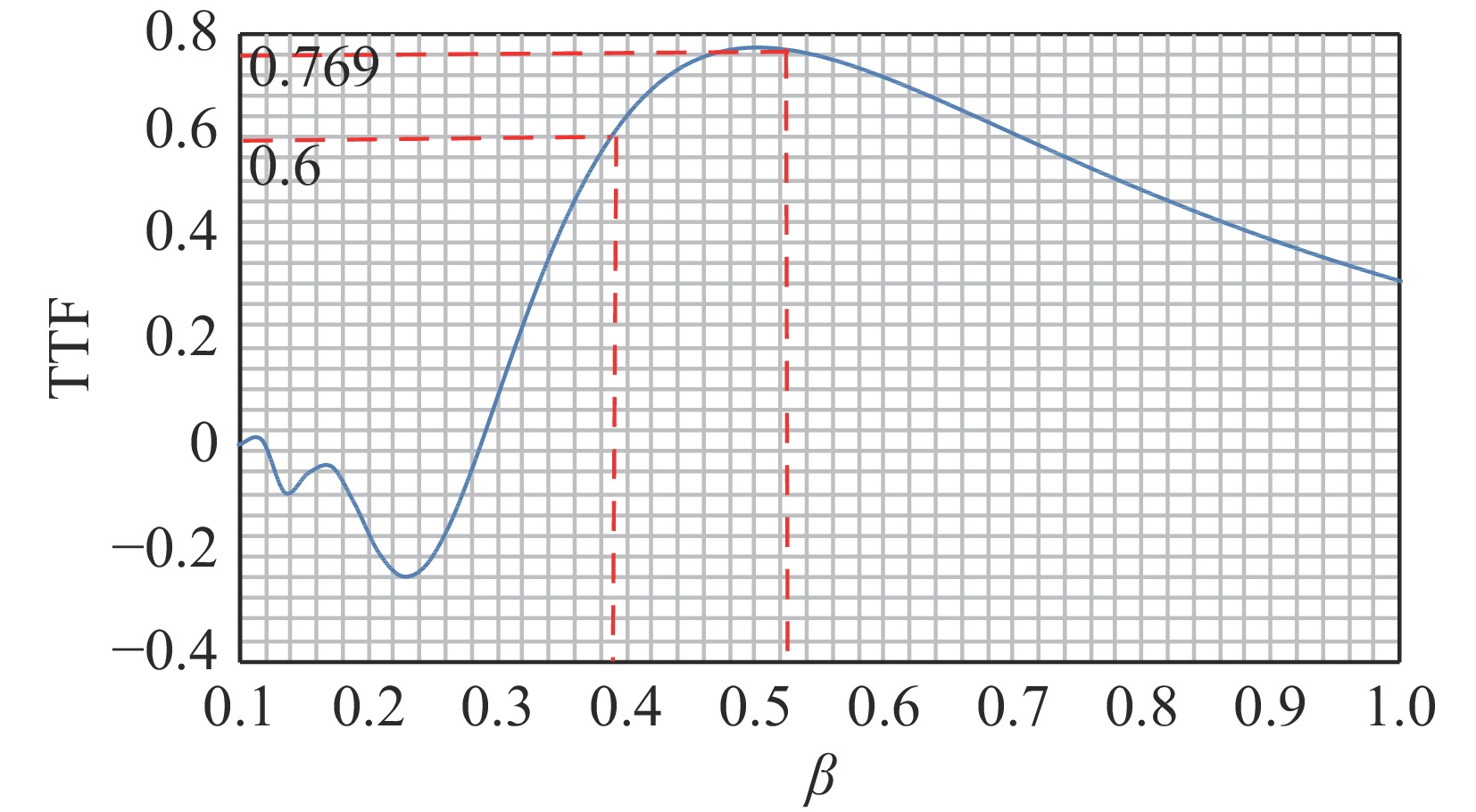

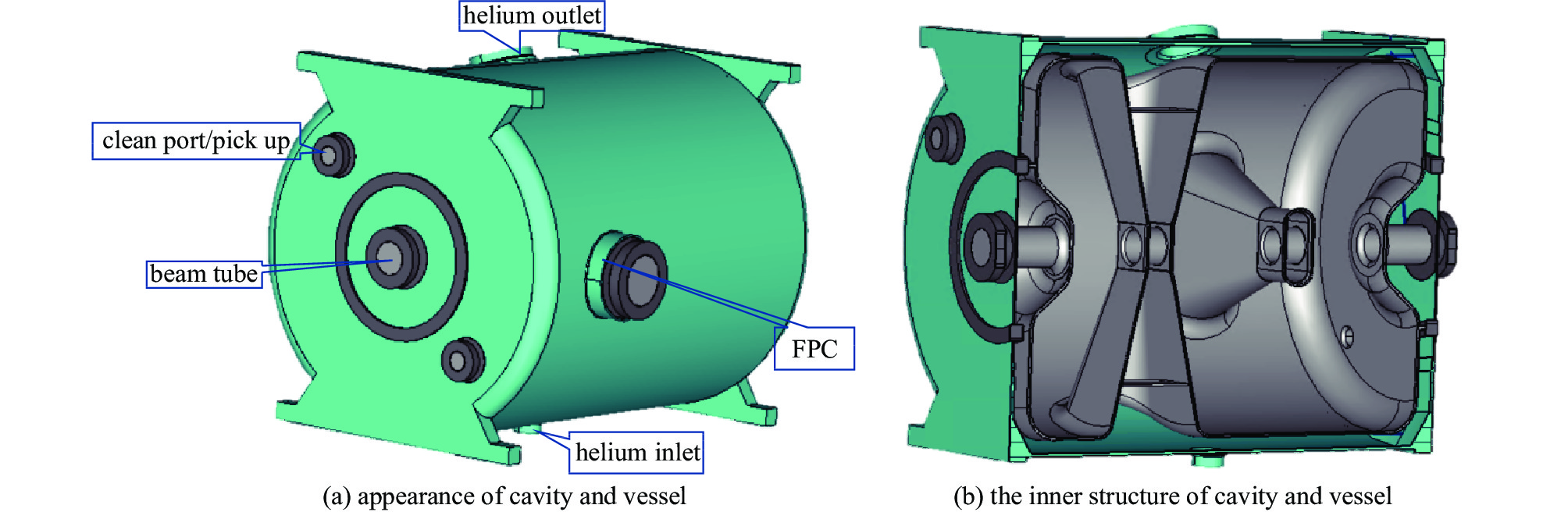

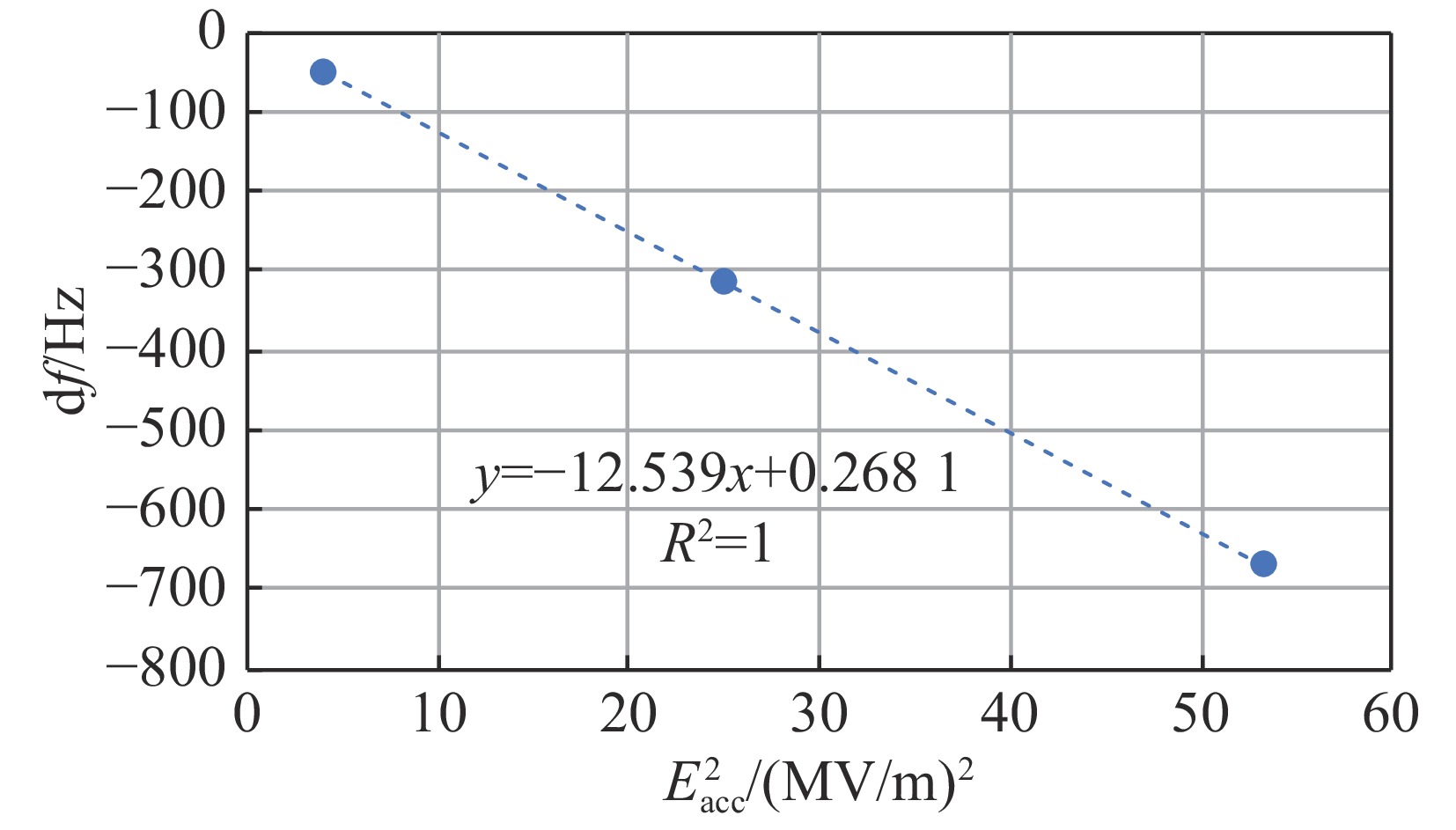

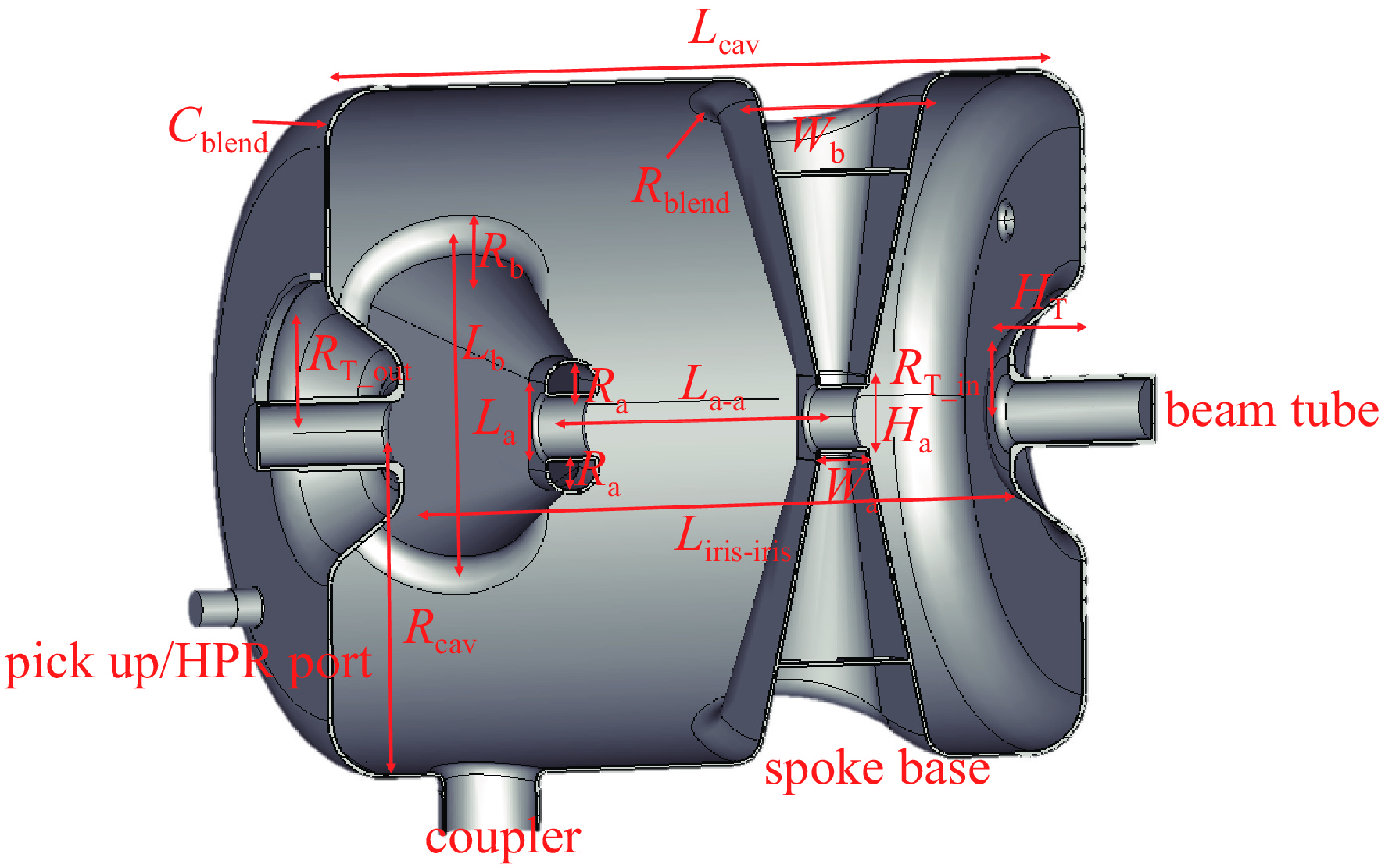

摘要: 中国散裂中子源是中国第一台、世界第四台脉冲型散裂中子源,其已于2020年2月达到100 kW功率的设计指标,运行稳定高效,供束效率位于国际前列。中国散裂中子源二期升级方案中总束流功率将升级到500 kW,其中直线加速器段将采用超导加速腔结构,束流能量由80 MeV提高到300 MeV。其中在80~165 MeV能量段采用324 MHz双spoke超导腔,在165~300 MeV能量段采用648 MHz 6-cell椭球超导腔。采用CST、COMSOL等仿真软件完成324 MHz双spoke超导腔的电磁、机械设计及优化,达到实际运行指标要求。为了提高腔运行的稳定性,在腔的设计中对EP/Eacc着重进行了优化,使其尽量降低。Abstract: The China Spallation Neutron Source (CSNS), located in Dongguan city, is the country's first and only spallation neutron source. It is also the fourth spallation neutron source in the world. It achieved the design index of 100 kW power in February 2020, and its operation is reliable and efficient. The total beam power will be increased to 500 kW in the CSNS phase II upgrade design, where the linac beam energy will be boosted from 80 MeV to 300 MeV and the peak current intensity will be increased from 15 mA to 50 mA by incorporating a superconducting linear accelerator. The double spoke resonator (DSR) will be used in the energy range of 80 MeV to 165 MeV. In the energy range of 165 MeV to 300 MeV, 6-cell ellipsoidal cavity will be used. DSR has many advantages, such as large velocity acceptance, which allows the spoke cavity to be used for a wider range of velocities, small size, high shunt impedance and a high coupling degree, which allows the production error requirements to be relaxed and the frequency bandwidth to be broadened from neighboring modes, among others. The DSR performance, including electromagnetic properties and machine parameters, was simulated and optimized using CST, COMSOL and other simulation software, and it achieved the requirement of CSNS phase II upgrade project. To improve the operating stability of the cavity, the design focused on minimizing Ep/Eacc.

-

表 1 双spoke腔主要电磁参数

Table 1. Main electromagnetic parameters of DSR

frequency/MHz β0 aperture/mm Ep/Eacc Bp/Eacc/(mT·MV−1·m) G/Ω (R/Q)/Ω operating gradient/(MV·m−1) 324 0.5 50 4.1 9.2 120 410 7.3 表 2 双spoke腔的基模频率和高次模频率

Table 2. Fundamental model frequencies and high order mode frequencies of double spoke resonator (DSR)

model frequency/MHz 1 324 2 354 3 386 4 503 5 505 6 548 7 603 8 604 9 613 10 658 表 3 材料在不同温度下的参数

Table 3. Material parameters at different temperatures

material Young’s modulus/GPa yield strength/MPa limit strength/MPa density/

(kg·m−3)Poisson’s ratio 295 K 4 K 295 K 4 K 295 K 4 K Ti 106 117 275 834 344 1117 4500 0.34 Nb 105 118 70 699 185 742 8560 0.39 Nb55Ti 62 68 476 476 545 545 6366 0.34 表 4 各个模式振动方式

Table 4. Vibration direction of each model

model vibration model vibration frequency/Hz 1 z-axis rotation 3.0 2 y-axis rotation 3.4 3 z-axis rotation 13.7 4 transverse vibration 34.3 5 z-axis simultaneous vibration 167.6 6 z-axis anisotropic vibration 174.7 7 z-axis rotation 196.3 -

[1] Hopper C S, Park H. High-velocity spoke cavities[C]//Proceedings of SRF2015. 2015: 943-947. [2] Hopper C S, Delayen J R. Superconducting spoke cavities for high-velocity applications[J]. Physical Review Special Topics - Accelerators and Beams, 2013, 16: 102001. doi: 10.1103/PhysRevSTAB.16.102001 [3] Krawczyk F L, Chan K C D, Gentzlinger R C, et al. An integrated design for a beta=0.175 spoke resonator and associated power coupler[C]//Proceedings of the 8th European Particle Accelerator Conference. 2002: 272-274. [4] Zaplatin E. Multi-spoke cavity end region analysis[C]//Proceedings of the 12th International Workshop on RF Superconductivity. 2005: 337-341. [5] Jiang T C, Xiong P R, Li C L, et al. Development of a superconducting double-spoke cavity at IMP[C]//Proceedings of the 9th International Particle Accelerator Conference. 2018: 2869-2871. [6] 周全. 高性能超导双spoke腔的物理与实验研究[D]. 北京: 中国科学院大学, 2021Zhou Quan. Physical and experimental studies of high performance superconducting double spoke cavity[D]. Beijing: University of Chinese Academy of Sciences, 2021 [7] Delayen J R, De Silva S U, Hopper C S. Design of superconducting spoke cavities for high-velocity applications[C]//Proceedings of 2011 Particle Accelerator Conference. 2011: 1024-1026. [8] Delayen J R. Low and intermediate beta cavity design—a tutorial[C]//Proceedings of the 11th Workshop on RF Superconductivity. 2015: 486-495. [9] Padamsee H, Knobloch J, Hays T. RF superconductivity for accelerators[M]. 2nd ed. Weinheim: Wiley-VCH, 2008. [10] Zheng Hongjuan, Zhang Pei, Li Zhongquan, et al. Design optimization of a mechanically improved 499.8-MHz single-cell superconducting cavity for HEPS[J]. IEEE Transactions on Applied Superconductivity, 2021, 31: 3500109. [11] Merio M. Material properties for engineering analyses of SRF cavities[M]. Fermi National Accelerator Laboratory, 2011. [12] Ginsburg C M, Reid C, Sergatskov D A. Magnetic shielding for the Fermilab vertical cavity test facility[J]. IEEE Transactions on Applied Superconductivity, 2009, 19(3): 1419-1422. doi: 10.1109/TASC.2009.2018234 [13] Jung Y, Joung M, Hyun M O, et al. Analysis of high pressure rinsing chacteristics for SRF cavities[C]//Proceedings of SRF2015. 2015: 414-417. [14] Guo H, Xiong P R, Shi Z X, et al. Study on local chemical treatment for recovery from surface oxidation by HPR process on SRF cavities[C]//18th International Conference on RF Superconductivity. 2017: 592-594. [15] Jones T, Pattalwar S, Burt G, et al. Determining BCP etch rate and uniformity in high luminosity LHC crab cavities[C]//18th International Conference on RF Superconductivity. 2017: 635-639. [16] Boffo C, Elementi L, Terechkine Y. Facility for chemical polishing of superconducting niobium RF cavities[J]. IEEE Transactions on Applied Superconductivity, 2005, 15(2): 2401-2404. doi: 10.1109/TASC.2005.849682 -

下载:

下载: